- 11 -

GB

Operating Instructions

Polymerization unit for hot- and cold-curing resins

9

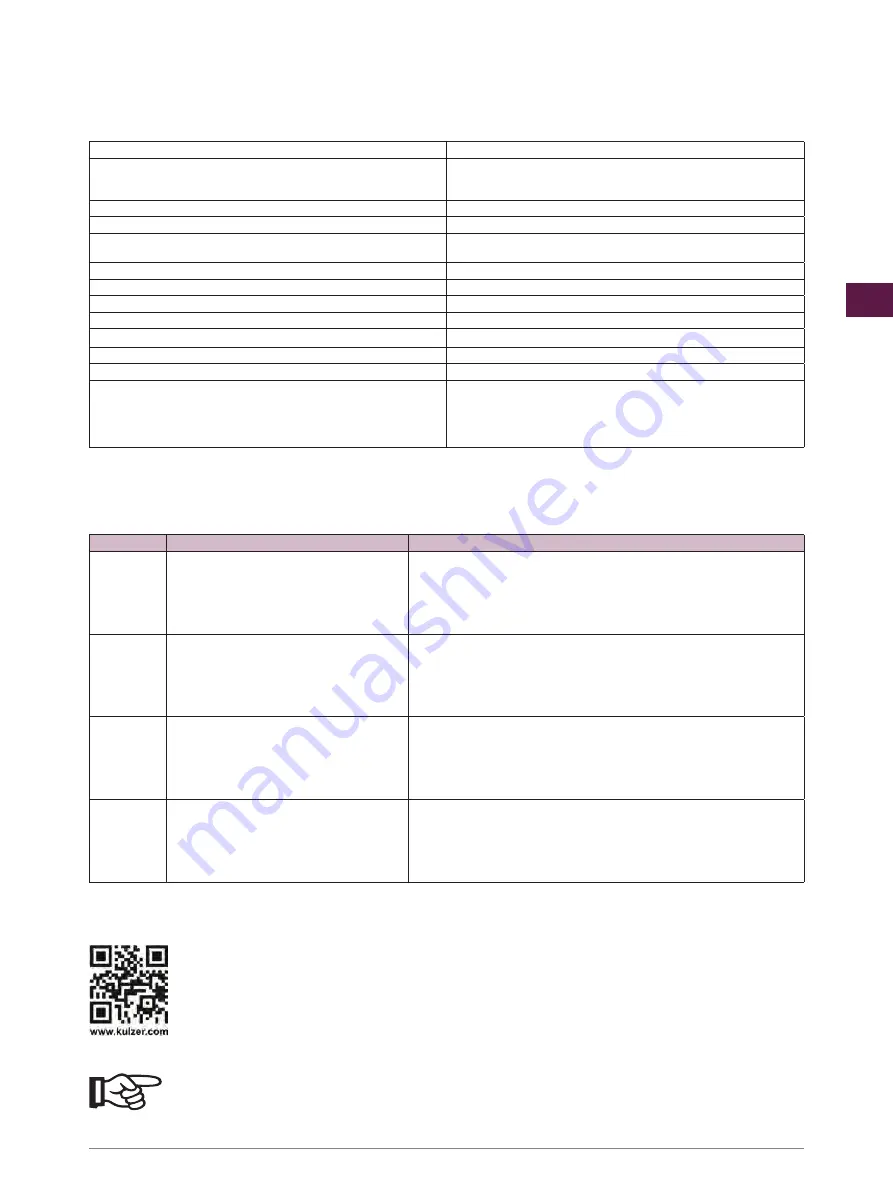

Technical data

Power consumption

650 W

Rated voltage / fuse type

100 V, 2 x T8A / 250 V

120 V, 2 x T6.3A / 250 V

230 / 240 V, 2 x T4A / 250 V

Nominal frequency

50 / 60 Hz

Voltage tolerance for all mains voltages

+-10%

Mains cable

EU - H05V2V2-F 3G 0.75 250VAC/16A

US - SJT3X18AWGWB105C C13/2,5m black 125VAC/15A

Protective class

1

Pollution degree

2

Pressure hose connection

3 to 10 bars

Nominal pressure

2 bars

Max. operating pressure

2.8 bars

Operating temperature of water

40 – 100°C (113 – 212°F)

Temperature limit

Dev / - 2.5 °C (4.5 °F) or approx. 5%

Height

Width

Depth

Weight

Dimensions

Required space

Height 300 mm

approx. 450 mm

Width 305 mm

approx. 315 mm

Depth 400 mm

approx. 550 mm

Weight 8.6 kg

10

Information on malfunctions

Error messages

Error

Cause

Remedy

E 98

Sensor break / short circuit (heating plate) or

automatic software - Safety shutdown due to

high temperature

- Press the Home button (11).

- Turn off the device

- Check water level (see section 7.2)

- Allow device to cool for approx. 10 min

- If the error persists, please contact your service partner.

E 99

Sensor break / short circuit (water bath) or

automatic software safety shutdown due to

high temperature

Press the Home button (11).

- Turn off the device

- Check water level (see section 7.2)

- Allow device to cool for approx. 10 min

- If the error persists, please contact your service partner.

E 18

Heating defect: If there is no temperature

increase after a defined period of time.

- Press the Home button (11).

- Turn off the device

- Check water level (see section 7.2)

- Allow device to cool for approx. 10 min

- If the error persists, please contact your service partner.

E 19

Heating control: If the control temperature

exceeds the target temperature for a defined

period of time

- Press the Home button (11).

- Turn off the device

- Check water level (see section 7.2)

- Allow device to cool for approx. 10 min

- If the error persists, please contact your service partner.

11 Service

We appreciate your comments, feedback, and suggestions.

Contact in the countries

and more information are

available by the displayed QR code

or at our website

www.kulzer.com

Micro USB port: (See section 5)

The USB port is used for software updates, which may only be performed by trained service personnel.

Therefore, customers are not permitted to connect USB cables/adapters, etc.

There is a risk of damage if not performed by trained service personnel!