- 3 -

GB

Operating Instructions

Polymerization unit for hot- and cold-curing resins

2

Information on safe operation

2.1

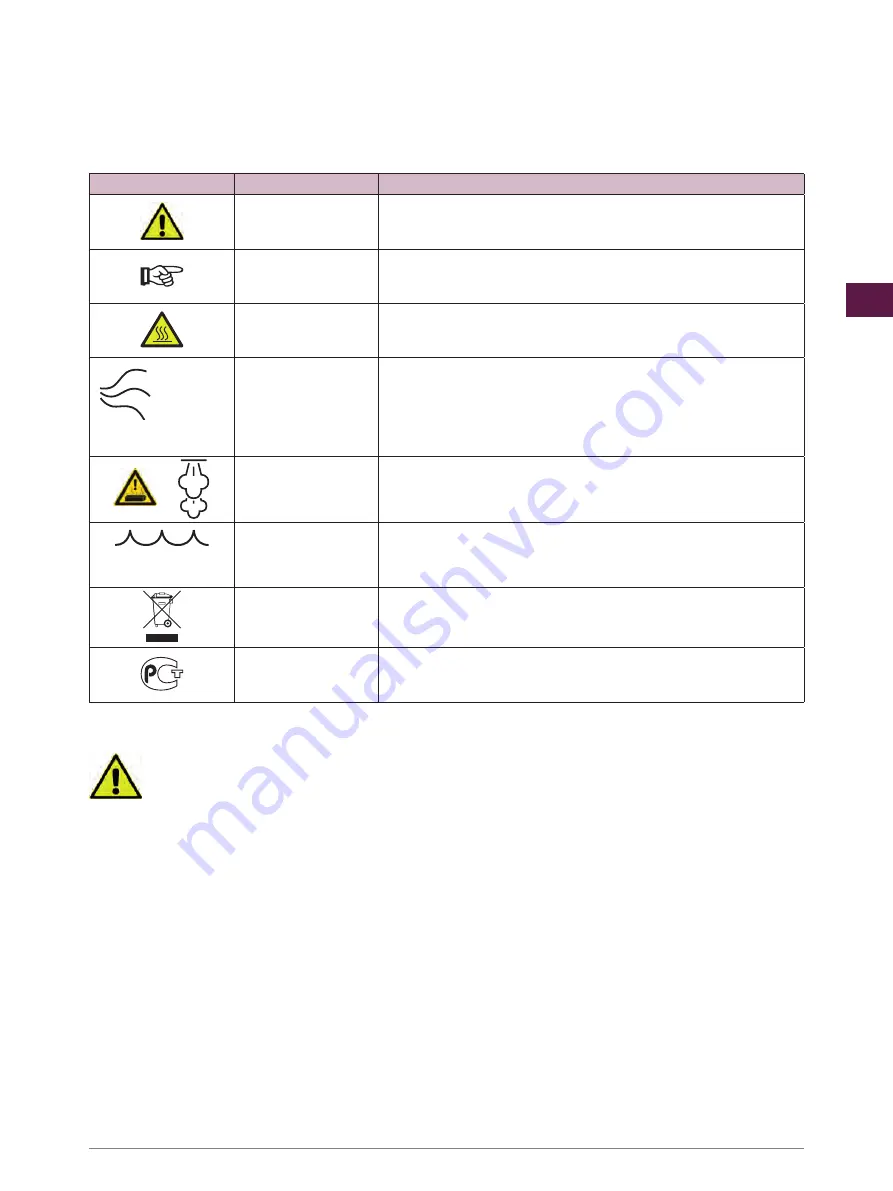

Explanation of symbols

Symbol

Text

Explanation

Attention!

Safety-relevant chapters and sections within these operating

instructions.

Note!

Information within the operating instructions on the optimum use

of the unit.

Hot surface!

Hot surface.

Risk of getting burned.

3 ... 10 bars

or designation

LUFT / AIR

Compressed air

supply

Connection – operating pressure 3 to10 bars.

or

Pressure release

Hot vapor.

Risk of scalding.

or designation

WASSER / WATER

Water drainage

Water drainage for emptying the polymerization pot.

WEEE

Disposal of old equipment according to WEEE

Electrical and Electronic Equipment Act (ElektroG).

Registration certificate according to the

ministry of health of the Russian federation.

2.2

Transport damage

The unit is sensitive to shock, because it contains electrical components. Particular care must therefore be taken

during transportation as well as storage. The equipment shipped by Kulzer was checked thoroughly prior to ship-

ment. The unit is correctly protected and packed when delivered.

Check the unit for damage after receiving it. If it is damaged, report this to the transportation company within 24

hours of delivery. Under no circumstances, install or work with a damaged unit.

2.3

Operator’s obligations

In addition to complying with the statutory regulations specified by the manufacturer, the operator must ensure the statutory

obligations are observed and implemented in the workplace, i.e. he must train his personnel and comply with industrial safety

legislation and any other regulations or laws in force.

For working on and with the machine, the operator must draw up written instructions in understandable form and give these

to his employees in their own language. These instructions must be based on the operating manual and written in light of the

work to be performed.

2.4

Unit book

We recommend to keep a unit book. All tests and essential works (e.g. repair work, modifications) must be documented

in this book.

Caution