6

5. Pre-heating

• The ring and mould former should be removed after the setting period. For safe positioning of the

mould, clean the top surface of the mould.

• Put mould and aluminium oxide press plunger in the preheating furnace.

HeraCeramPress pellets and Heravest disposable press plunger must not be preheated.

• Heat the mould (Linear or Speed heating – according to the instructions for use of the investment

material) to 850 °C.

• Holding times: 200 g mould

➙

60 min

100 g mould

➙

60 min

Note: With Speed heating, the holding time starts when the furnace has reached again the final

temperature!

6. Pressing

• Activate the press programme.

• Take mould out of the preheating furnace when the press furnace has reached the start temperature

of 700 °C.

• Place 1 – 2 HeraCeramPress pellets in the mould channel.

• Place press plunger in the channel (disposable press plunger or aluminium oxide press plunger).

• Put immediately the mould so assembled in the press furnace and start the press programme.

• After pressing, remove the mould from the press furnace and allow to cool to room temperature.

Avoid cooling of the mould between removal from the preheating furnace and the start

of pressing procedure

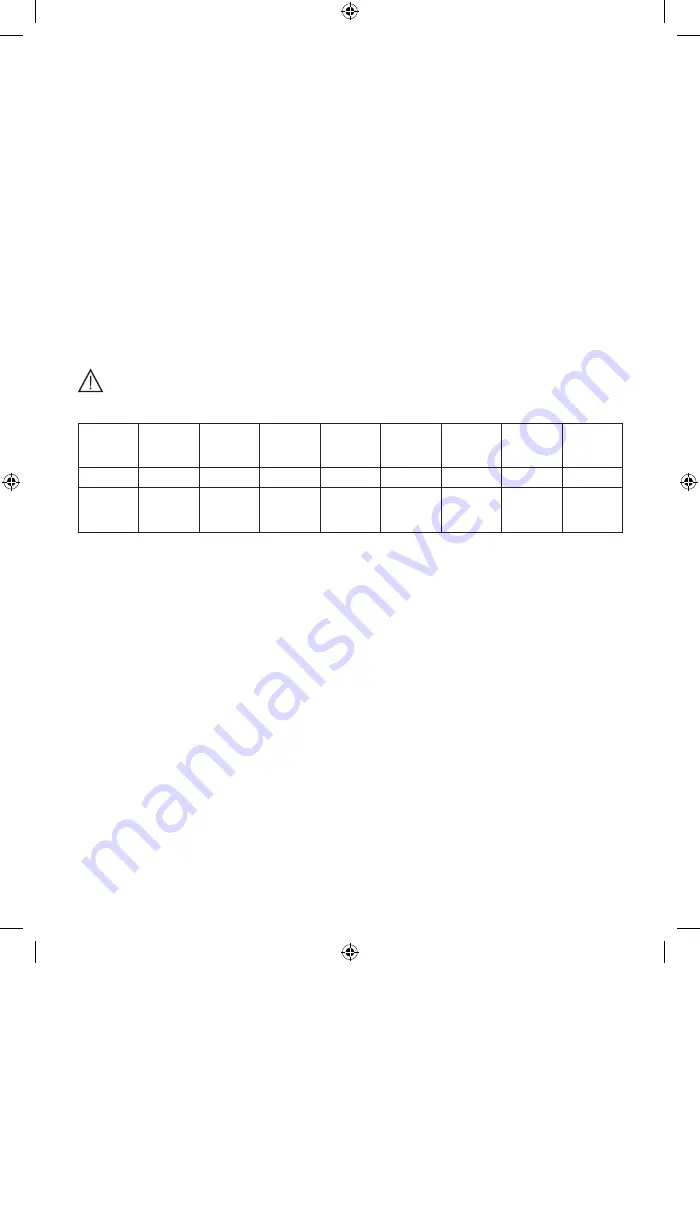

General Press Recommendation

Start

tempera-

ture

Vacuum

start

Vacuum

stop

Vacuum

Heat rate

Final

tempera-

ture

Hold

Pressing

Pressure

force

°C

°C

°C

hPa

°C/min

°C

min

min

bar

700

700

1030

30

50

1030

15

8

depending

on type of

furnace

7. Deflasking

• Determine and mark the position of the pressed objects with the aid of a press plunger. Then make

a deep cut into the investment material with a cut-off wheel at the end side of the press plunger.

Separate the investment parts from each other through a rotating movement.

• Remove investment material by means of cautious sandblasting.

Note: Avoid localised sandblasting which will cause overheating of the surface.

Do not use aluminium oxide

• Rough investment removal with glass beads (4 bar, 50 µm, do not use a recycling blasting unit) - do

not completely expose the objects yet.

• Complete investment removal: continue to blast extensively on the surfaces using reduced pressure

(1.5 bar max., 50 µm, glass beads).

Finishing

Pressable ceramic must be processed in (water-)cooled conditions. Apply low pressure so that the

pressable ceramic do not overheat and no cracks occur. Use diamond abrasives which are preferably

in mint condition. Please pay attention to the minimum thickness of the inlays (2.0 mm minimum in the

isthmus) and the veneer shells or crown copings (0.8 mm).

• Avoid localised overheating when separating and grinding the sprues.

• Fitting the objects on the model: fit carefully on the die. In case of precontacts, thinly stain the die

with occlusal paste / spray. Remove precontacts carefully using fine diamonds.

Note: Wear a face mask and eye protection when grinding ceramic materials and work with an

extraction unit. Avoid inhaling the ceramic dust.

• Clean object with a steam cleaner. Avoid overheating.

1809_15440_GBA_HeraCeram_Press.indd 6

21.12.18 10:24