- 10 -

GB

DE

GB

FR

ES

IT

PT

NL

SE

DK

NO

FI

GR

7.6.3 Filter drawer

Has the filter been inserted?

Clean or replace very dirty filters.

7.6.4 Inside the machine

Has the flash lamp been inserted as far as it will go?

Has the chip card been correctly inserted into the card reader?

Is the filter disc in position and clean?

8 Appliance

8.1

Working with the machine

Connect the machine to the power supply and switch it on.

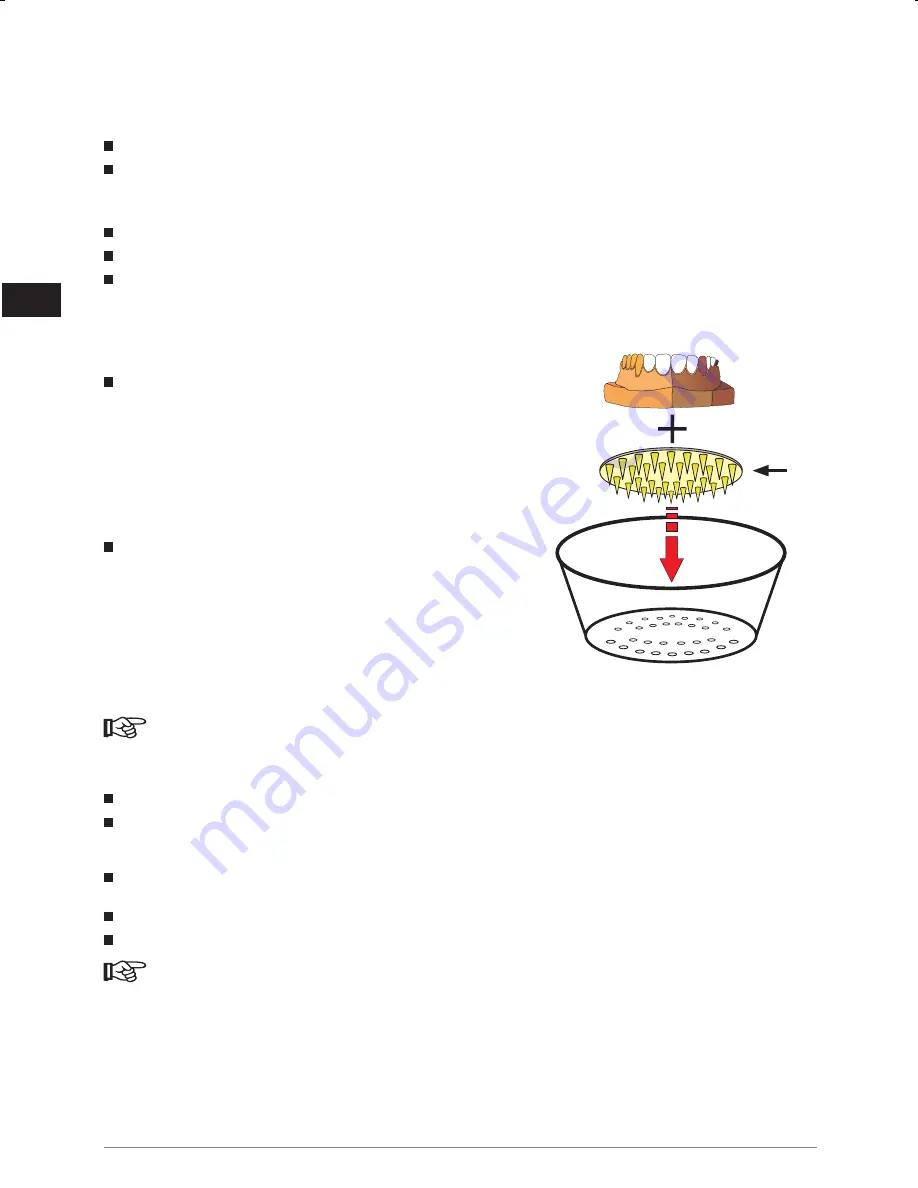

Make sure that the material is placed in the machine on the supplied object

holder (if possible!) and not with the whole plaster model. The large light

reflector allows this to be done, but it significantly prevents the cooling

capability.

Warming can be reduced with the “

Model tray

” spacer when the 180 second

light polymerisation is used frequently. For this purpose, the model must

be placed on the tray with the feet pointing downwards in order to achieve

better ventilation.

Delivery form:

2 pieces “

Model tray”

REF 66017525

Open the polymerisation drawer and insert the prosthetic material in the light

reflector. Close the drawer. Press the button for the respective polymerisation

cycle. The respective LED ring is lit.

The drawer is locked (not in the 6 second cycle). At the end of the polyme-

risation time an acoustic signal (buzzer) is heard and the drawer is unlocked

again. Remove the prosthetic restoration and exchange the reflector pot if it

is heavily contaminated or clean it.

The fan which started at the beginning of polymerisation continues to run until the interior of the unit has been cooled down

to a large extent.

NOTE

The built-in ventilator must cool the prosthetic material evenly and well to ensure an excellent polymerisation result.

This will only happen if the product is positioned in the centre.

Observe the following information:

Place the prosthetic material in the centre of the light reflector.

Align the polymerisation product with the light source to ensure an excellent polymerisation result. If polymerisation is

advantageous on the model, place the model with the greatest possible angle to the light reflector wall. This keeps the

ventilation holes in the floor free. An angular position is favourable as lateral exposure is better on the facing.

When positioning the product, ensure that it is aligned beneath the edge of the light reflector. Otherwise,

the drawer will not close and the object will touch the window pane in the machine.

Insert the drawer as far as it will go.

Select the required polymerisation time and press the button.

NOTE

The 6 second polymerisation time is used to harden the material. All components of Signum

®

(exception: Opaque)

can be pre-polymerised using the 6 second polymerisation time if a maximum layer thickness of 2 mm is not exceeded.

Then carry out intermediate polymerisation for 90 seconds and end polymerisation for 180 seconds.

To ensure extended service life of the unit, the interior of the unit should have been cooled down sufficiently before the

unit is switched off. The unit should not be switched off as long as the fan is not in standby-mode. (Fan is not turned

off completely).

Attempting to pull out the drawer may result in blocking of the locking magnet. In such cases the drawer needs to be

re-inserted and the unit must be switched off and on; then the drawer can be opened again.

Model tray

Summary of Contents for HiLite power

Page 1: ...DE Betriebsanleitung GB Operating instructions HiLite power DE GB...

Page 2: ......

Page 18: ...16 DE 14 Schaltplan 14 1 Klemmenbelegungsplan...

Page 20: ......

Page 36: ...16 GB 14 Circuit diagram 14 1 Terminal allocation scheme...

Page 38: ......

Page 39: ......