Model A

Page 39 of 47

4.5.5Auto Angle Adjustment Instructions

1. The circular blade angle adjustment is to improve the early machine in cutting different widths

materials to ensure the smooth cutting surface and must change different circular blades at different

angles. At present only one circular blade is enough to change the cutting angle to ensure smooth

surface and this machine can set different angles ranging from

±

8.0

。

2. How to apply this function?

If the material must trim firstly, usually, the trimming would produce slope and not smooth surface, so

please set the blade holder in negative angle about

3

4 to perform the trimming, and then make the

right cutting according to the necessary angles. The angle range is decided by the cutting widths, usually

cutting some hard materials, the smaller the width, the bigger the angle, and vice versa. When cutting the

semi finished products, the force of contact surface is big and would affect the blade feeding resistance,

then cutting the material tail part the relative trimming motion would be produced. Please set the blade

holder angle ranging from +3-+4 to cut the tail part, then the qualified product is ensured and reduce the

unqualified products.

3. Application:

The machine cutting in same shaft has twenty different widths and twenty cutting angles with

automatically cutting.

4. Applicable methods

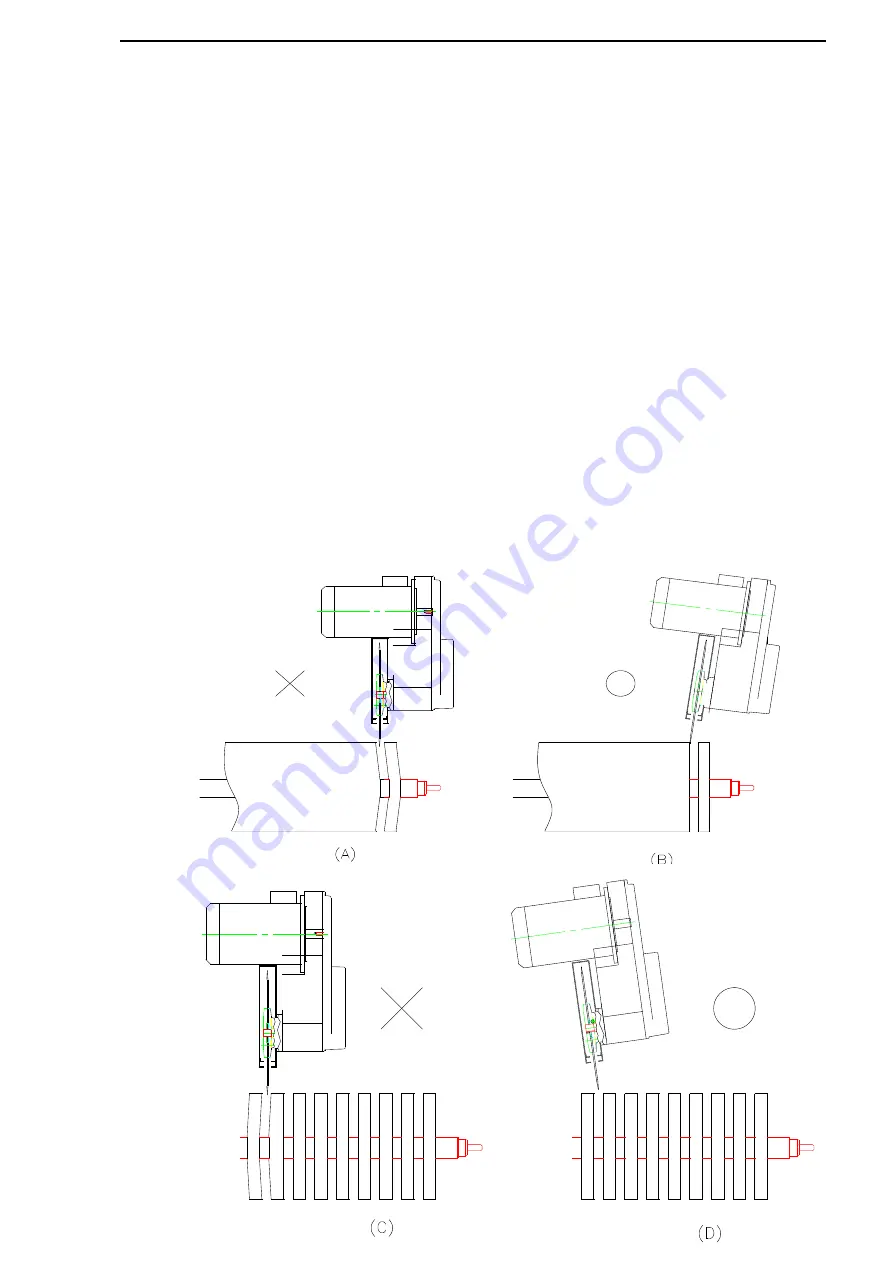

(1) Using blade C in the first trimming as different materials, the cutting forces are different and the

finished products would easy to deform the finished products (picture A). Then we can change the

cutting angle to the negative direction, and then we can make the finished surface smooth (as in B).

Usually adjust within -4~-6

°

according to different materials.

(2) Using blade C to finish the last cutting. Because of different forces, the final finished products may have

deformation as in picture C and affect the quality, then the blade holder angle

Summary of Contents for FR-1300A

Page 5: ...Model A Page 3 of 47 1 3 safety position drawing...

Page 11: ...Model A Page 9 of 47 2 5 machine dimension...

Page 15: ...Model A Page 13 of 47 3 4 Installation method Model FR 1300AB Model FR 1600AB...

Page 18: ...Model A Page 16 of 47 3 7 Gas circuit...

Page 20: ...Model A Page 18 of 47 4 Operation 4 1 operating position Model FR1300AB FR 1600AB...