DRUM SANDER FOR WOODEN FLOORS

ARLEQUIN

ED 04

PG.

13/19

USE AND MAINTENANCE HANDBOOK

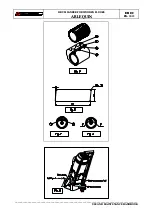

ARLEQUIN CLASSIC (drum for classic type)

Abrasive has to be prepared in the dimensions indicated in

fig. E

and it has to be cut absolutely with the

inclination which is showed in the picture. By means of the proper keys, turn the two tensioning shafts

pos. 1

e 2 fig. F

until the two flat sides of the tensioning shafts are face to face. Insert one abrasive edge for approx.

2/3 of the drum cut depth and turn the drum being careful that the abrasive sticks to the rubber; once you get

to the cut, insert the other edge of the abrasive until it is uniformly stretched. Take the two edges out of the

cut, uniformly, for approx. 5 mm., as shown in

fig.

F.

Turn the tensioning shafts one opposite the other until

you get the right and regular tensioning of the abrasive. In the end, the

P

planes of the shaft have to be

approx. as indicated in

fig. G.

In case the abrasive should not be uniformly tight, after carrying out the a.m. operations, please repeat the

instructions adjusting the introduction of the abrasive until you get the correct and regular tensioning. The

a.m. procedure is needed for setting of coarse grain abrasive

(20-24).

For medium and fine abrasive

(36-60-

80 etc…)

. it is necessary to put one or even more abrasive stripes between the two edges, which should be as

large as the drum and of approx. 30 mm. of height, in order to compensate for the difference in thickness

between the coarse and the medium/fine grain abrasive

WARNING:

The abrasive is in the correct position when it protrudes from the sanding

drum by about 1.5 mm.

DANGER:

If you use abrasive which is damaged or not well tightened, it may tear

while sanding and cause damages to the machine and to the floor

PERIODIC MAINTENANCE

To keep the machine in good working order, the following items must be periodically checked and maintained:

VACUUM UNIT (for the user)

Check periodically the condition of the fabric filter, by eliminating the residues with a slight shaking of the same

filter. The continual and correct use of the paper bags, which are to be used once and then thrown away,

prevents in any case every risk of stoppage of the filter.

DUST BAG (for the user)

Remove the bag and replace it before it is completely full. Do not use the paper bag again but always

substitute it with a new one.

DRUMS (for the user)

Check periodically the external surface of the sanding drum. Remove any dirt.

WHEELS (for the user)

Remove periodically any dirt from the machine body and wheels. Accumulated dirt, modifing wheels planarity,

may cause undulations on the sanded surface.