29

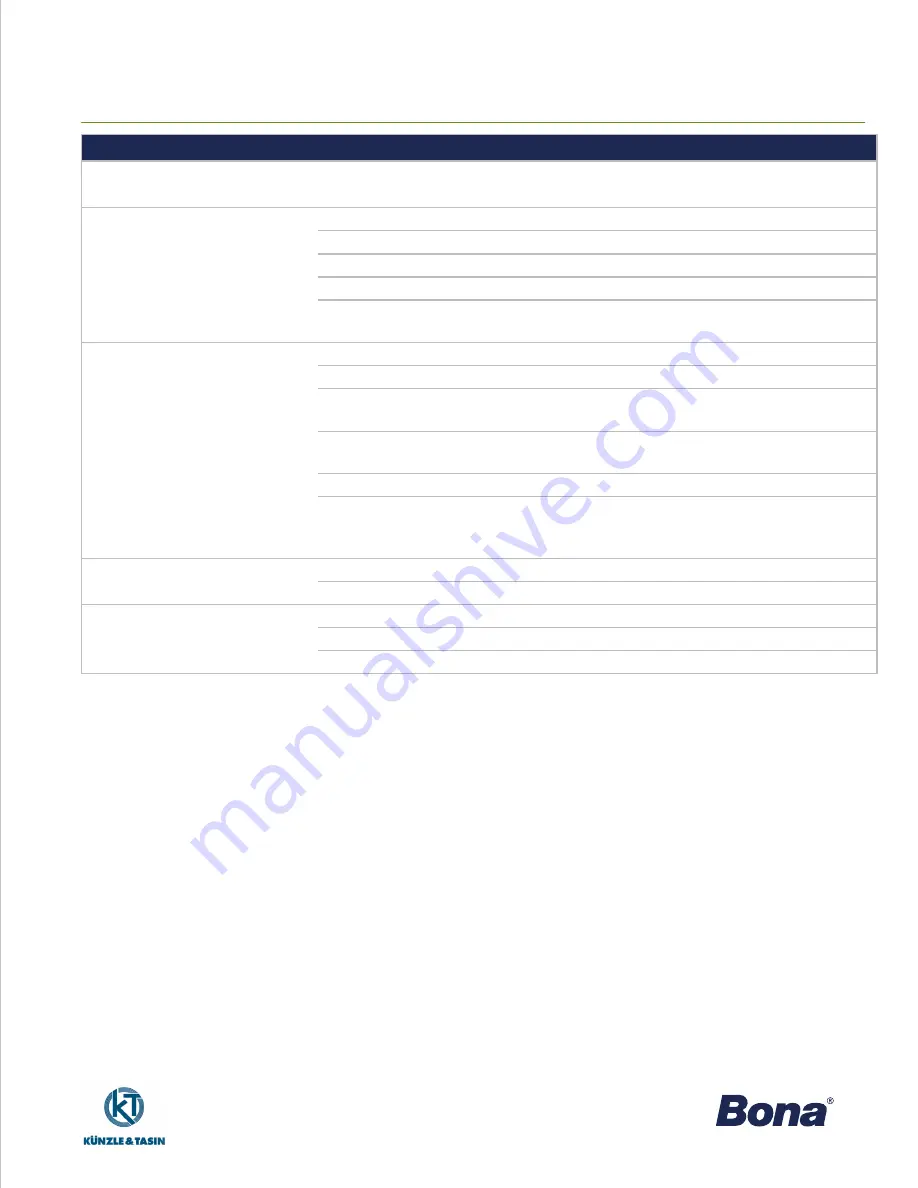

Emergency Situations (for the user)

Faults

Causes

Solutions

FAULTS

CAUSES

SOLUTIONS

The drum doesn’t come off

enough from the floor

Wheels joint, between the two parts of the

drum lifting rod, not properly adjusted

Adjust it

The abrasive doesn’t sand

enough or its speed is not

enough or it doesn’t keep the

right place

Unsuitable or worn-out abrasive

Replace the abrasive

Insufficient drum pressure

Adjust the drum pressure at the maximum level

Dust prevents adjusting the drum pressure

Remove the dust

Belt tension at a wrong value

Set it at a right value

Worn-out driving belt or pulleys or bearings

Replace the driving belt or contact an authorized Bona

dealer for pulleys and bearings replacement

The floor surface is not regu-

larly sanded

Faulty abrasive

Replace the abrasive

Incorrect wheel adjustment

Correct the wheel position

Bearings, pulleys or shafts dirty or faulty

Clean them or contact an authorized Bona dealer for re-

placement

Driving belt and wheels dirty, badly adjusted

or faulty

Clean, adjust or replace them.

Drum surface dirty or faulty

Clean, correct or replace the rubber-coated drum

Drum surface out of roundness

Replace the rubber-coated drum and remember never to

let the drum laying on the floor while the machine is not

working in order to avoid ovality

Scorching on work surface

Worn-out abrasive

Replace the abrasive

Excessive pressure on drum

Decrease sanding pressure

Insufficient dust collection

Dust bag more than 1/3 full

Replace it

Filter cloth guard dirty

Shake out the dirt and wash or change the filter guard

Vacuum ducts and/or obstructed pipes

Clean air ducts