Summary of Contents for 634 Series

Page 1: ...a y y k NKL a_ NNQFJ a_ NMQFJ a_ NLLFJ a_ NKLFJ...

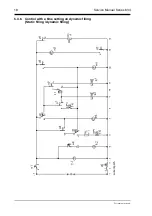

Page 38: ...38 Service Manual Series 634 For internal use only 9 3 Circuit diagrams IG 634 2...

Page 39: ...Service Manual Series 634 39 For internal use only...

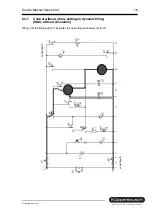

Page 42: ...42 Service Manual Series 634 For internal use only 9 6 Circuit diagrams IG 644 2...

Page 43: ...Service Manual Series 634 43 For internal use only...

Page 46: ...46 Service Manual Series 634 For internal use only customer service test program only...

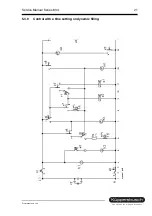

Page 47: ...Service Manual Series 634 47 For internal use only 9 9 Circuit diagrams IG 669 2...

Page 48: ...48 Service Manual Series 634 For internal use only...

Page 49: ...Service Manual Series 634 49 For internal use only 9 10 Circuit diagrams IG 659 2...

Page 50: ...50 Service Manual Series 634 For internal use only...

Page 52: ...52 Service Manual Series 634 For internal use only 9 12 Circuit diagram S0 60 0489...

Page 60: ...60 Service Manual Series 634 For internal use only 9 18 S0 60 0540 IGV 659 2...

Page 61: ...Service Manual Series 634 61 For internal use only 9 19 Circuit diagrams S0 60 556...