6. Changing and setting the burner injectors

6.1 Cooking zone burners

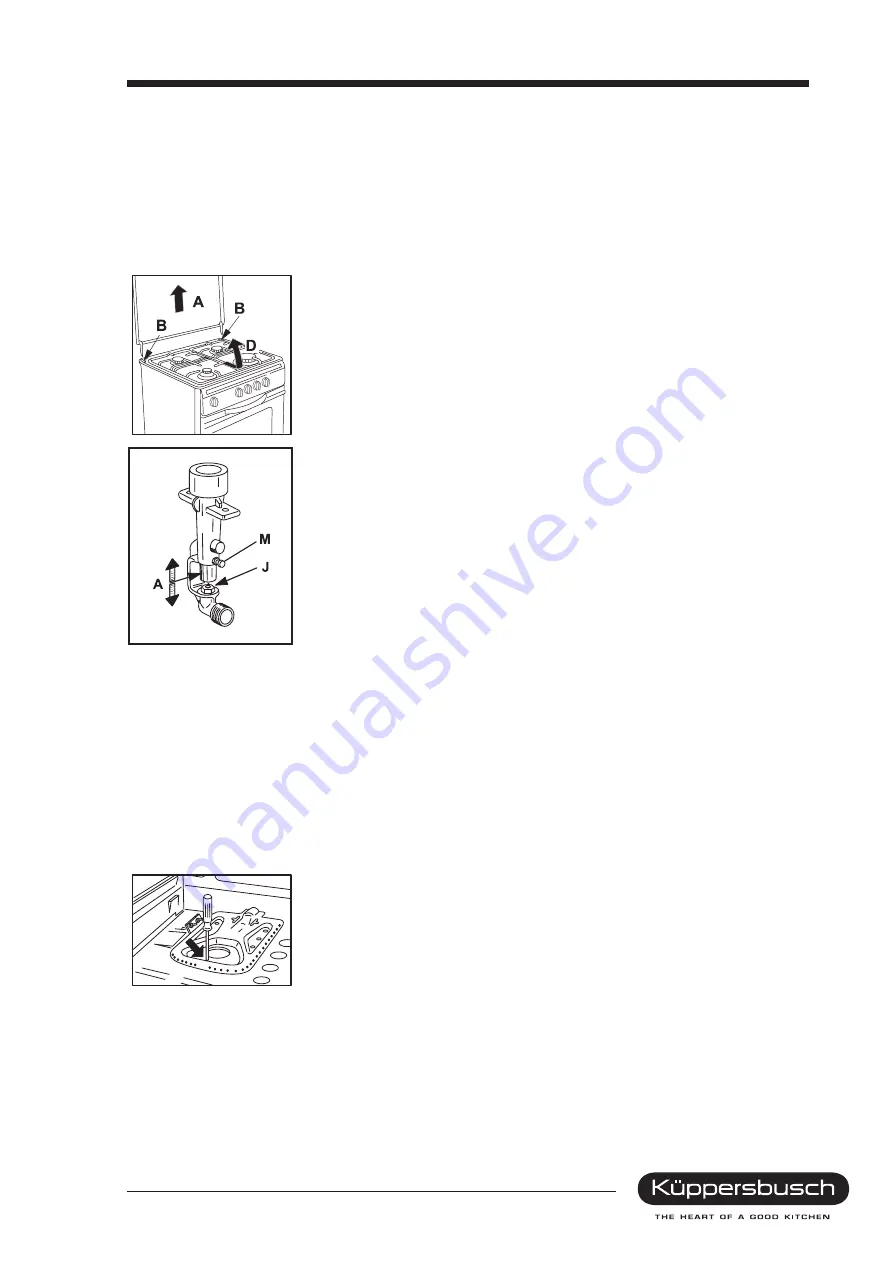

To replace the injectors of the cooking zone burners, the cooker hob must be lifted out.

To this end proceed as follows:

Pull cover plate A upwards and remove.

Undo screws B with holders.

Remove ribbed grid and burners from the cooker hob.

Pull hob forwards, lift up and position leaning backwards.

Loosen the screw M of the injector carrier and lift the tube for air

control A right out.

Unscrew injector J with a polygonal spanner (size 7) and replace it

with an injector which is prescribed for the gas being used (see table).

6.2 Regulating the primary air

Ignite the burner and check whether the flame is regular. Should an adjustment be necessary, regulate

the air with the tube A.

Oven and grill

Ignite the burner and check whether the flame is regular.

Should an adjustment be necessary, move the bushing until you have

found the correct setting.

Then tighten the screw.

Regulation of the primary air is exactly right when there is enough safety

against flame lift when the burner is cold and against light-back when the

burner is hot.

Technical manual GH 606.0 E/GH 506.0 E/GH 505.0 E/GKH 507.0 E

19

For internal use only