Service Manual IW 1209.0W / IWT 1259.0W

81

For internal use only

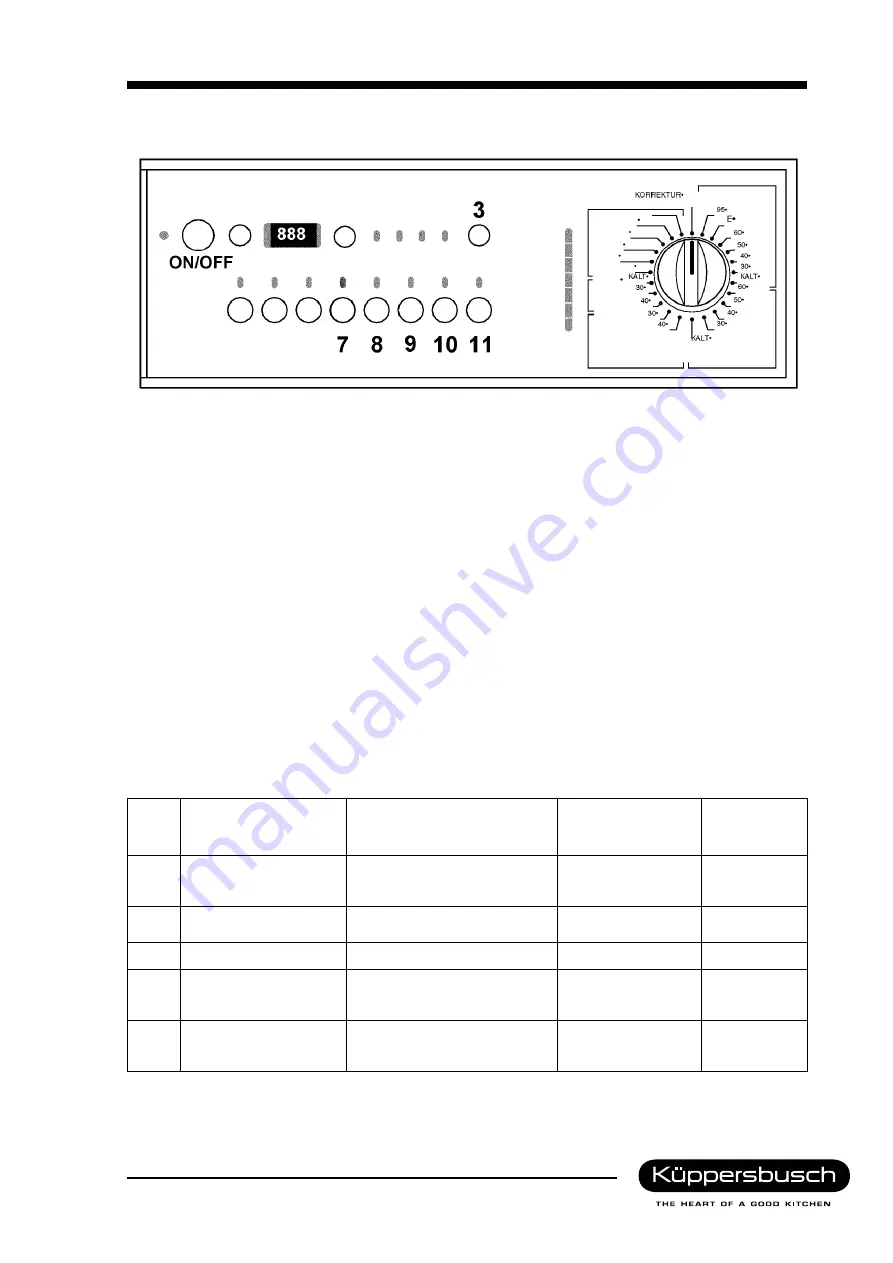

14.4 Diagnostic Programme - Drying

This diagnostic programme provides a semi-automatic check of all components used by the machine

during the drying programmes.

Accessing the Diagnostic Programme

Switch the machine on using the

ON/OFF

button, at the same time holding down buttons

8

and

10

.

Press buttons

7

and

9

within

five seconds

.

If you have successfully activated the diagnostic mode, you will see

"t04"

in the display for 3 seconds.

The diagnostic programme is subdivided into individual programme phases; one or more components

can be tested during each phase. It is possible to exit certain of the phases before completion by

pressing the

11

button.

All of the fault code functions are active and are displayed during each phase.

Press button

3

to view a number of variable parameters. First, the parameter reference appears briefly

(PO1, PO2 etc.), then its value.

P1:

Water level (mm)

P2:

Condition of safety pressure switch 1(0-1)

P3:

Condition of half-power thermostat (0-1)

P4:

Motor speed (rpm x 10)

P5:

Position of water inlet valve (0 – 16)

P6:

Outlet duct NTC thermistor, drying (°C)

P7:

NTC thermistor, drying - condenser (°C)

Phase

Test

Loading Activated

State at End of

Phase

Exit from

Phase

Possible

1

Calibration electron.

pressure switch

Drain pump, inlet valve

The tub is emptied

when the calibration

is finished.

NO

2

Condenser fan

Motor fan

Condenser solenoid valve

Timeout

(10 Minuten)

JA

3

Drain

Drain pump, inlet valve

Empty level reached

NO

4

Drying, half-power

One rod of the dryer heating

element

Closing of ½ power

thermostat

Half-power

NO

5

Drying (full power)

Both rods of the dryer heating

element, motor fan,

condenser solenoid valve

Timeout

(10 minutes)

YES

Summary of Contents for IW 1209.0W

Page 1: ...GB Integrated Washer Dryer IW 1209 0W IWT 1259 0W...

Page 3: ...GB Washing Programmes and Programme Functions VF 92J VP91J Multipanel Versions...

Page 17: ...Service Manual IW 1209 0W IWT 1259 0W 17 For internal use only 4 SPIN PROGRAMMES...

Page 18: ...18 Service Manual IW 1209 0W IWT 1259 0W For internal use only...

Page 19: ...Service Manual IW 1209 0W IWT 1259 0W 19 For internal use only...

Page 20: ...20 Service Manual IW 1209 0W IWT 1259 0W For internal use only...

Page 21: ...GB Built in Washing Machine IW 1209 0W Part B...

Page 39: ...GB Built in Washer Dryer IWT 1259 0 W Part C...

Page 68: ...68 Service Manual IW 1209 0W IWT 1259 0W For internal use only...

Page 69: ...GB Fault Indicator and Test Programmes Electronic Washing Machines Multipanel Version...

Page 80: ...80 Service Manual IW 1209 0W IWT 1259 0W For internal use only Spin phase 12...