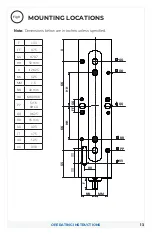

13

OPERATING INSTRUCTIONS

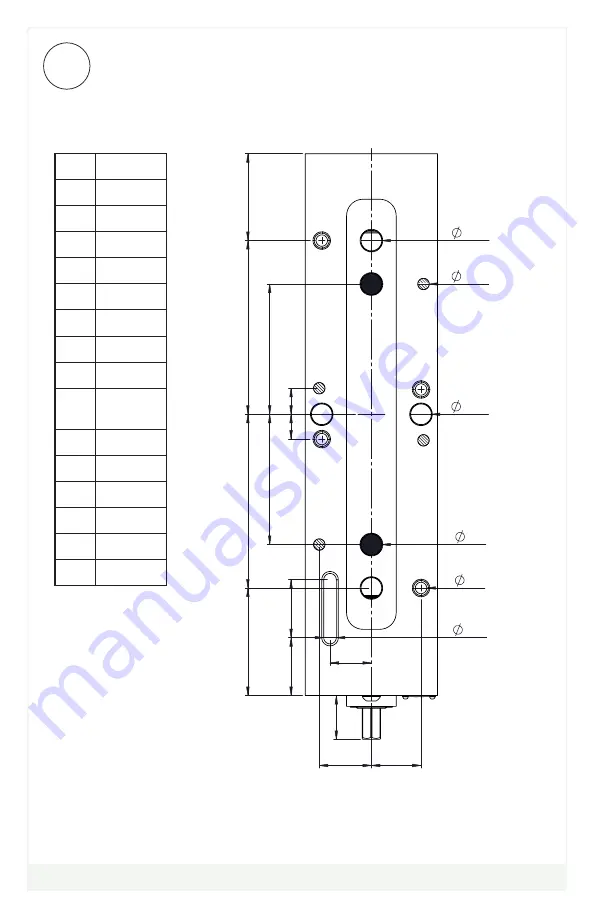

MOUNTING LOCATIONS

F

1.33

FF

0.75

GG

0.787

HH

50 mm

II

II 2.625

KK

5.25

MM

1.5

NN

40 mm

OO

M8 SHCS

PP

5/16

SHCS

0.625

RR

16 mm

SS

3.25

TT

1.75

UU

1.25

VV

0.38

Fig.9

PP

OO

RR

FF

GG

HH

HH

II

KK

KK

SS

TT

TT

MM

NN

UU

F

VV

Note:

Dimensions below are in inches unless specified.