17

MAINTENANCE SCHEDULE

MAINTENANCE SCHEDULE

It is very important to perform regular maintenance on your Kurt vise to

ensure proper operation. Improper maintenance will result in poor vise

performance and may void your warranty.

Daily/ Weekly

1. Remove chips from surface of vise.

2. Visually inspect seals for damage and cleanliness.

3. Visually inspect for chip entrapments and remove when necessary.

4. Air-dry and apply rust inhibiting oil to the machined surface of the vise.

Monthly

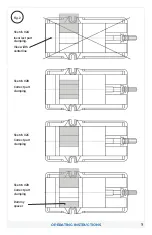

1. Open the vise to the maximum opening.

2. Slide the Jaw slightly toward the stationary jaw and lift up to remove

the jaw from the “beak” of the nut.

3. Turn the movable jaw over and clean the inside cavity.

4. Remove chips, clean and apply a light coat of machine oil to the

machined surface of the following item:

a. Nut & Screw assembly (clean exposed threads on the screw)

b. Bed of vise (top of “rails”)

c. Inside of the vise between the center ways.

5. To re-assemble the movable jaw, press down on each of the quick

jaws to lock into place

6. Your vise is now ready for use. Open and close your vise to check for

proper operation. Center the part to be clamped in the vise and close.

Your parts should be centered from side to side to ensure proper

clamping.

3 to 6 months

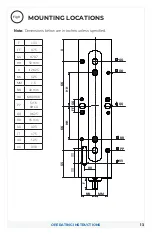

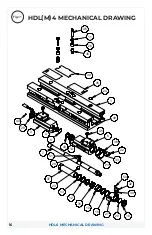

1. On the HDLM4 (manual-long) model, start by removing the M8 button

head cap screw (#49- Fig. 11) located under the holding block and

threaded into the vise body. (See Fig. 7 for parts list)

2. Remove rear station movable jaw.