18

MAINTENANCE SCHEDULE

3. Place a 3.25” thick spacer in the front station, and start closing the vise

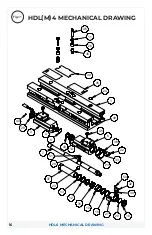

and this will drive the holding block (#27 in Fig. 11) out of the vise body.

4. Once the holding block is clear of the body, reverse the screw rotation,

so the spacer can be removed.

5. Remove the stationary and front movable jaws from the vise.

6. Remove the chip guards

7. The nut and screw assembly can now be slid out freely from the vise.

8. Thoroughly clean and oil the nut and screw assembly, vise body, and

jaws so there are no chips or debris left.

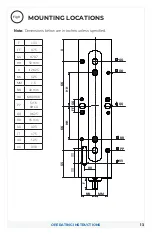

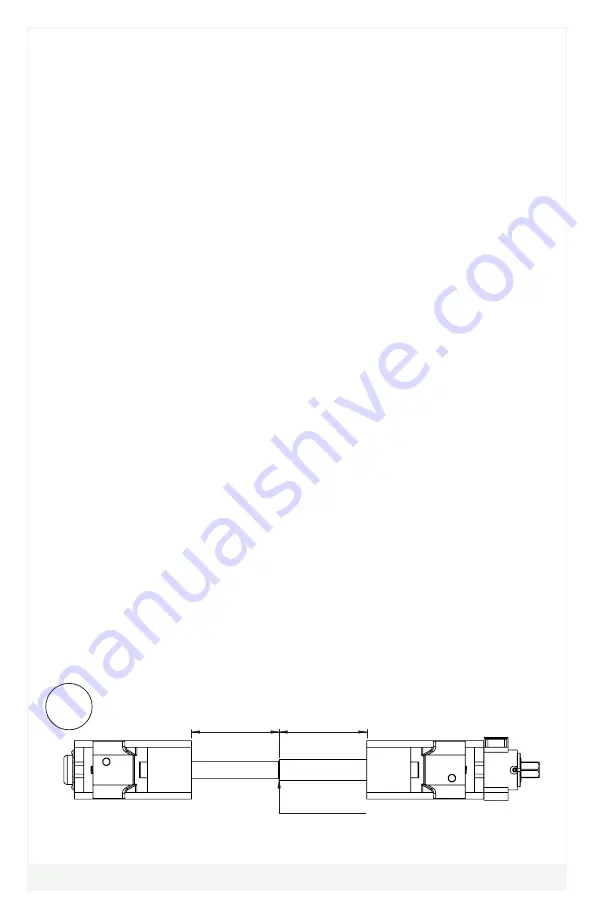

9. Now it’s time to reset the timing. Turn the rear nut counter clockwise

until you can feel resistance. Turn the nut back the other way until the

front and rear front are in line with one another. This sets the timing of

the front and rear nut. (See Fig. 12 below)

10. Slide the nut and screw assembly, rear nut first, into the vise body up

to the holding block. See Fig. 11 for holding block identification.

11. Install stationary and rear movable jaws. Place a 3.25 spacer in the

rear station and start closing (clockwise rotation) the vise. You may

have to help get the friction clamp (rectangle piece with tapered ends)

started into the body by using a pair of pliers to help compress the

spring material.

12. Once the holding block is inside the body, reinstall the M10 button

head cap screw in the end of the body. Install front movable jaw.

13. Your vise is now ready to use.

MAINTENANCE SCHEDULE

Fig.12

4.125"

4.125"

Screw Shoulder

Reset Timing - Rotate Nuts until the 4.125" Spacing above is achieved