40

3BA00226 • 2016-11-16 • Rev. 2

Ersa HR 200

TOP HEAT

Smooth

Intensive

Power

level

1

2

3

4

Time*

>180 s

180 - 120 s 120 - 90 s

90 - 60 s

1

Ultra light

weight

Sensitive bottom

side

Intensive

top

2

Sensitive

top side

Typical SMT

application

3

4

Intensive bottom

HEAVY

DUTY

CAUTION

*expectable soldering time, depending on application

and preheating with bottom heater

B

O

TT

O

M

H

EA

T

In

te

ns

iv

e

Sm

oo

th

PA

R

A

M

ET

ER

S

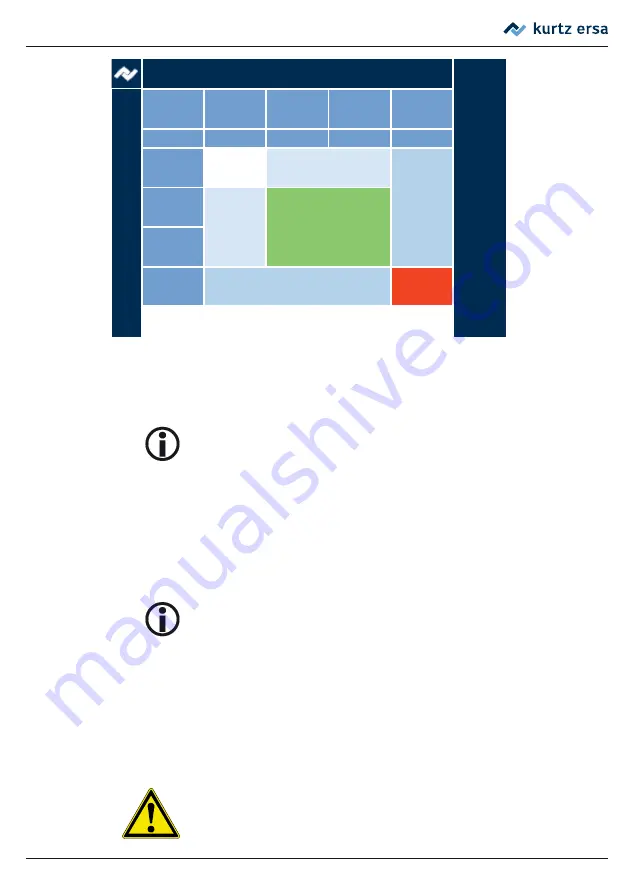

Parameter diagram: recommended heat output for PCB types during soldering

and desol-

dering. This diagram is attached as a chart to the housing of the HR 200 and can also be

called up on the Internet at www.kurtzersa.com.

The heating plate IRHP100A is in standby mode at 30% output and

switches to the set output level when the foot switch is pressed.

■

By pressing the foot switch, the heating process of the top heater and – if enabled –

of the bottom one is started.

■

When the solder is molten, remove the component with an appropriate tools and

release the foot switch. If necessary, switch off the bottom heater using control knob

⑪

or the mains switch of the heating plate.

We recommend using fume extraction system (e.g. Ersa EASY ARM 1).

6.3.3

Soldering

■

Position the PCB in the PCB holder at a distance of about 30 mm below the top heater.

■

Prepare the soldering point on the PCB with flux and/or solder paste. Then place the

component.

CAUTION! Hazard of material damage!

Also adjacent areas are heated and must, therefore, be protected against

heat if necessary.

Function description