7 | Tutorial – Soldering or desoldering a component

Task 4 "Preparation"

7.10 Task 4 "Preparation"

If you selected the dip mode [No automation] (soldering without flux material dip

and without component with solder paste in the print template):

a) With the aid of the laser, position the component to be soldered in the middle

and properly align it on a component tray. Then the component is lifted from

the component tray. Then the component must be aligned and placed in sol-

dering position.

If you selected the dip mode [Auto. Dip], e.g. for QFN components:

a) With the aid of the laser, position the component to be soldered in the middle

and properly align it on a component tray.

b) With the doctor blade apply flux material gel in the dip template and place the

dip template into the other component tray.

Then the component is taken from the component tray and dipped in the flux ma-

terial of the dip template. Then the component must be aligned and placed in sol-

dering position.

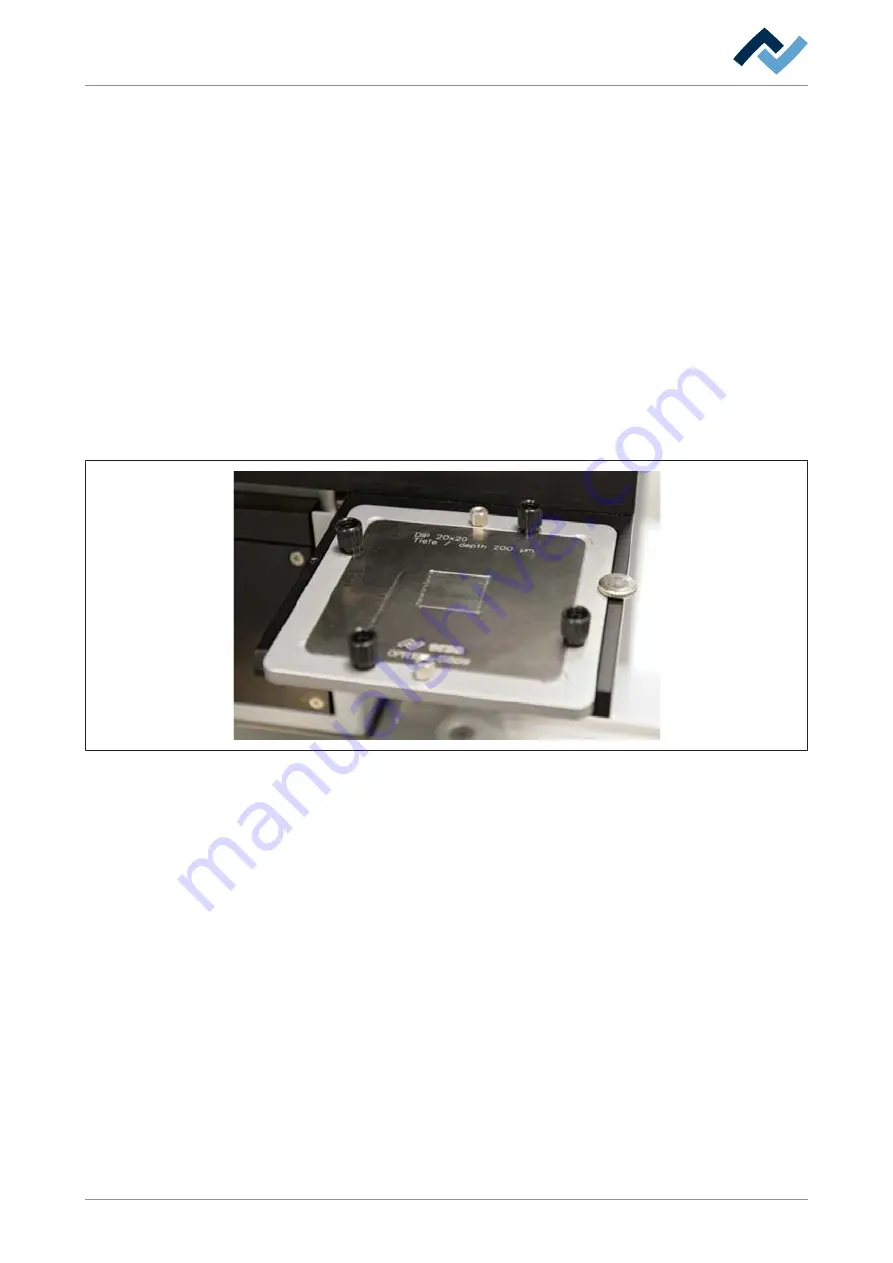

Fig. 31:

Dip template covered in flux material on the component tray

a) After applying flux material gel with the doctor blade in the dip template, place

the dip template in the other component tray.

If you selected the print mode [Auto. Print]:

a) With the doctor blade, apply solder paste on the bottom of the component.

b) Place the print template in a component tray and make sure it is correctly

aligned with the component.

The component is lifted by the print template. Then the component must be

aligned and placed in unsoldering position.

Ersa GmbH

Operating instructions HR 550 XL EN 3BA00247-01 | Rev. 1

131 / 157