15

7.0. Damping:

A damping system, consisting of a paddle, damping trough and silicone oil, can also be

retrofitted on all Air Line tonearms.

The paddle is fixed on to the threaded rod and the trough is fixed on to the blocking plate.

With oil levels, paddle height, damping can be changed from zero to max. This is suitable for

cartridges with high compliance.

Note: Do not use the damping facility while levelling the tone arm! The tonearm will not

move freely.

Inserting silicone oil:

Cut off the tip of the nozzle from PVC bottle. Squeeze silicone oil into the trough- it will go

slowly before it spreads evenly. Fill it up to the line or about half way up.

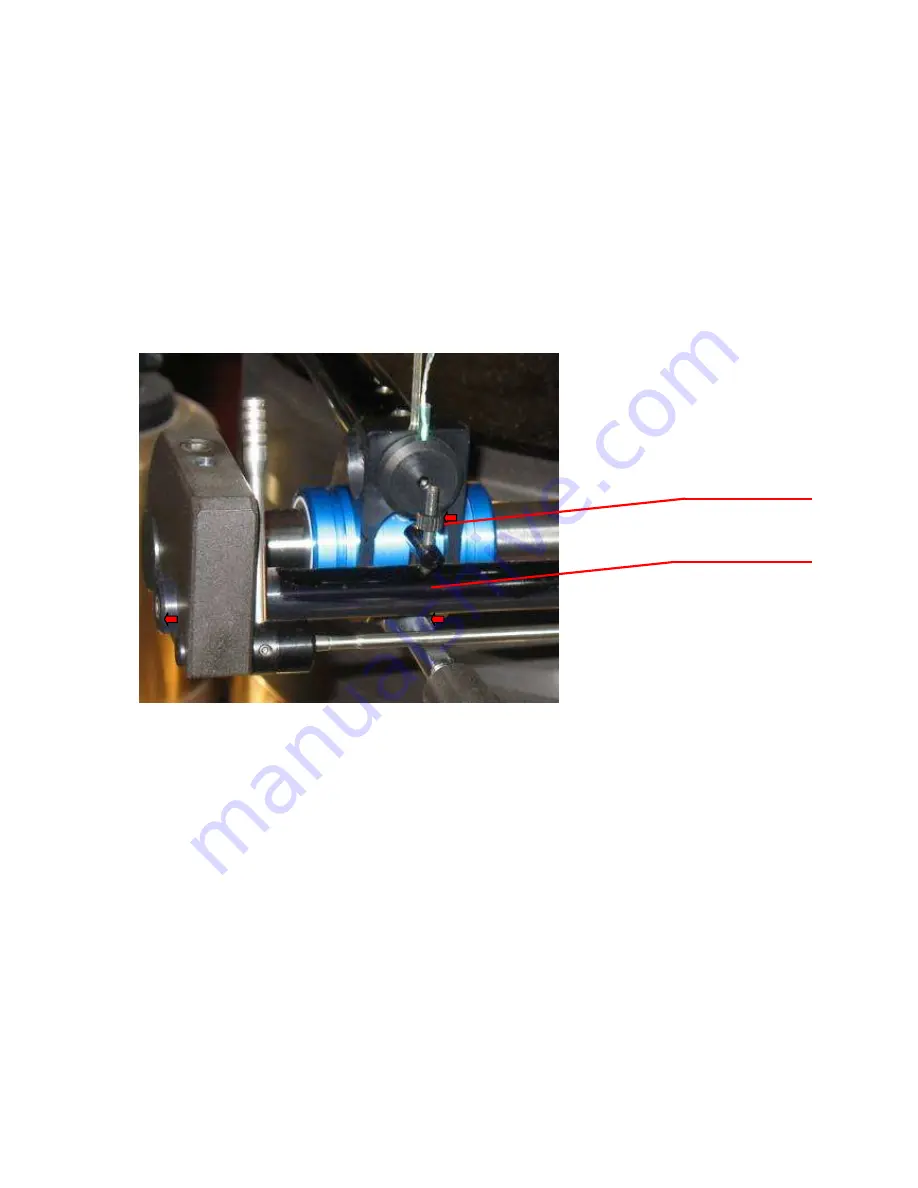

Damping system

Damping change:

Release black plastic nut by hand and rotate the paddle-screw into the trough with

Allen key 1.5mm. To secure paddle at the desired height, fix it with the rotating CCW plastic

nut, while preventing paddle - screw rotation with an inserted Allen key.

Optimisation:

The only way to reach optimum damping is by experimentation. Start with the height

of the paddle when the needle is in the groove so that the tip of the paddle is just

touching the surface of the silicone oil. Listen to the sound and increase the depth.

Also observe what happened when the needle touches the grooves, how the whole

assembly moves in a horizontal level a few times, before stabilising in the groove. If

you have a test record observe how the damping decreases movement of the assembly

when resonance occurs.

For a lot of cartridge combinations the best sound will be without the use of damping.

But cartridges with higher compliance might benefit.

Damping trough

Damping paddle