About the Hopper

KVAL 777 Operation/Service Manual

2-10

About the Hopper

Important:

Do not put Magnetized Screws in Hopper. Magnetized

screws can cause sluggish response to screws getting

stuck. Hopper plates could get magnetized and will have

to be demagnetized with a degausser.

Important:

Do not adjust any of the Hopper air cylinders. They are adjusted at the

factory. Any adjustment may cause timing issues with the operation of

the Four Shooter. If you think problems are being caused by the cylin-

ders, please contact the KVAL Service Department for direction.

Important:

Do not mix screw types in the Hopper. Different sizes, pitches can cause

uneven application of the hinge.

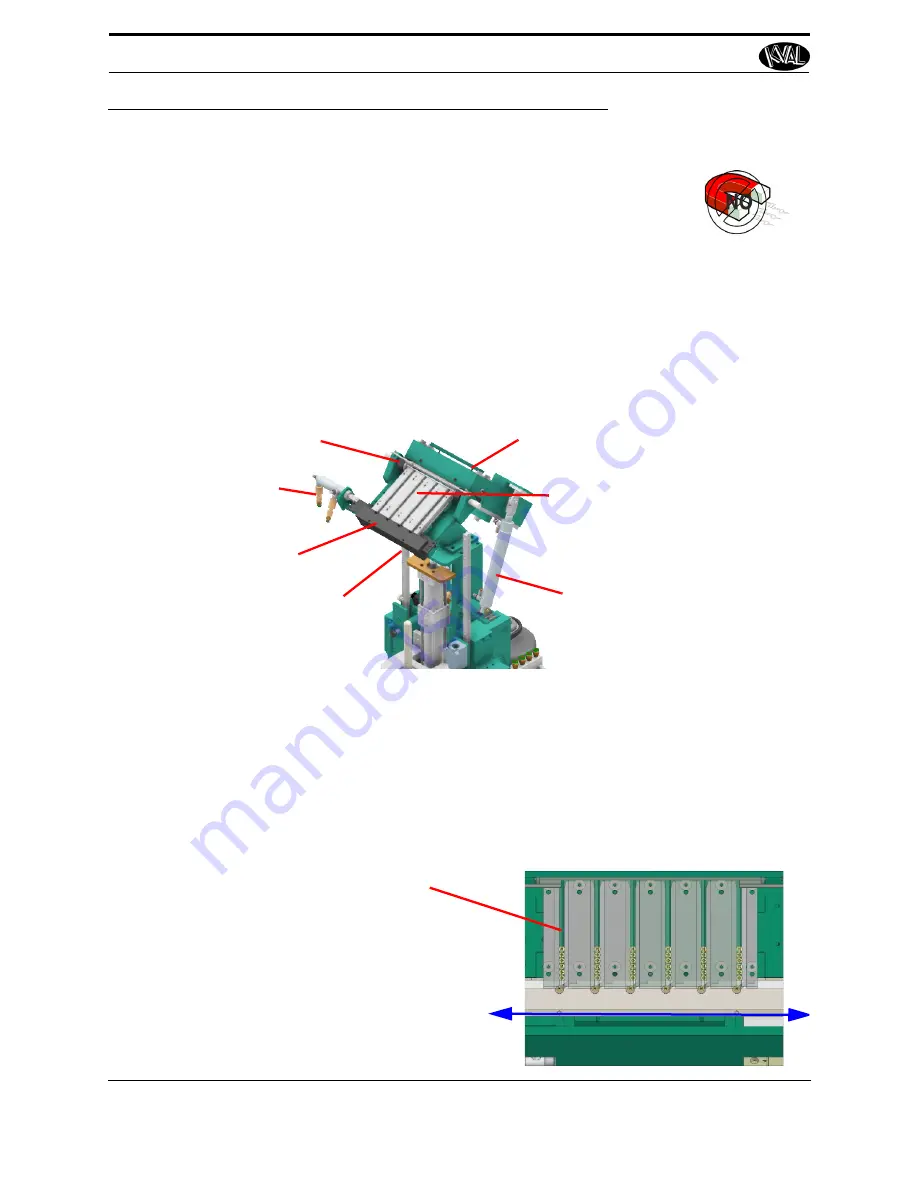

Hopper

Gate Assembly

Screw Tracking Plate

Assembly

Hopper Cylinder

Screw Delivery Tubes Air Injected:

Not seen. Plastic tubes that deliver

screws to the Hinge Applicator

Plate Assembly Cylinder

Screw Pick Off Slide

Hopper Process

1.

Pour Screws into the

Hopper

.

2.

The

Hopper

moves up and down periodically during the process by the

Hopper Cyl-

inders

to organize the screws and deliver them to the

Screw Tracking Plate

.

3.

The

Gate Assembly

monitors the quantity of screws delivered to the to the

Screw

Tracking Plate Assembly

.

4.

The screws are stacked in the slots of the

Screw Tracking Plate Assembly.

5.

The

Screw Pick Off

Cylinder

moves the

Slide Assembly

to capture four screws at a

time.

6.

Each tube has air injectors to speed the

delivery to the

Screw Receiver Tubes

.

Summary of Contents for 777

Page 4: ...KVAL 777 Operation Service Manual ...

Page 23: ...Getting Help from KVAL 1 15 KVAL 777 Operation Service Manual Page Intentionally Left Blank ...

Page 48: ...Description of the Six Light Panel KVAL 777 Operation Service Manual 2 24 ...

Page 92: ...Troubleshooting with the Status Light Panel KVAL Operation Service Manual 1 20 ...

Page 95: ......