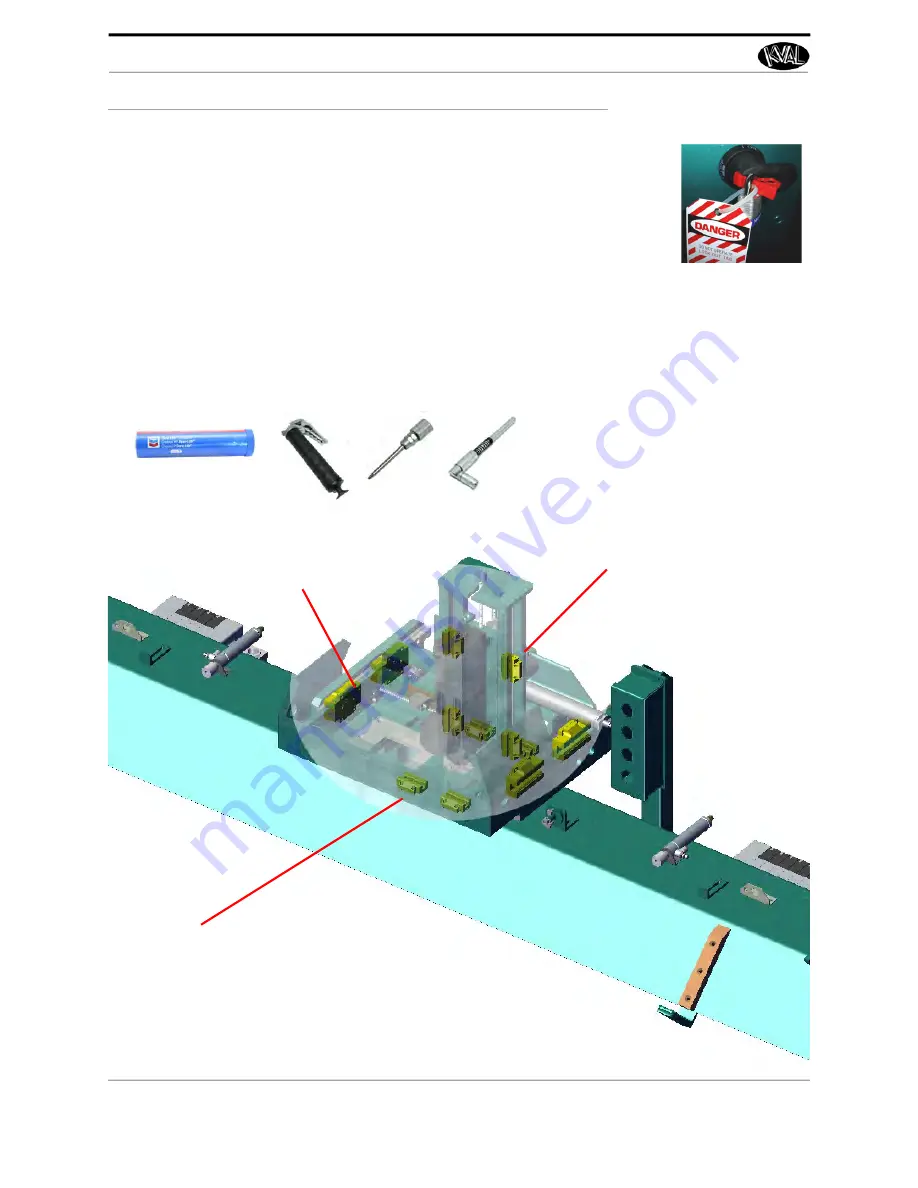

Sample of Grease Locations for 960-3

KVAL Operation/Service Manual

3-8

Sample of Grease Locations for 960-3

Bearing Locations

Use an extender to reach tight areas. Make sure to

Lockout/Tagout

before maintenance. For rec

-

ommended greasing schedule,

see “Lubrication Requirements” on page 3-6.

This machine is a powerful electro-mechanical

motion control system. If servicing this machine, fol

-

low the safety guidelines. Failure to do so can result in

damage to equipment and/or serious injury to person

-

nel.

Shutdown the machine and follow the

“Lock Out

Tag Out procedures

Caution

Linear Bearing Housings Z axis (X4)

Every 250 Hours of Machine Opera

-

tion

Linear Bearings X axis (X4)

Linear Bearing Housings

Y axis (X4)

Summary of Contents for 960-3

Page 4: ...KVAL 960 3 Operation Service Manual ...

Page 28: ...Safety Sign Off Sheet 1 21 KVAL Operation Service Manual ...

Page 46: ...Description of the Light Tower KVAL Operation Service Manual 2 18 ...

Page 64: ...Appendix Collet Torque Values KVAL Operation Service Manual 3 18 ...

Page 65: ...Appendix Collet Torque Values 3 19 KVAL Operation Service Manual ...

Page 67: ...Notes ...