Step 2: Calibrate the Stops

3-11

965X Operation Manual

Step 2: Calibrate the Stops

At the

Calibration Screen

, select

Jamb Stops

Procedure to Calibrate the Stops

In this calibration process, cut a known shape on the jamb. Mea

-

sure the

location

of the cut.

1.

Before calibrating the tools, make sure the

Tool Con

-

figurations

are up to date.

See “About the Tool Config

Tabs” on page 2-29 .

2.

Create a

Job

of your choice.

For Example:

Create a 2.0 '' square, with chiseled corners, a middle predrill 44.0 '' from the top reference.

3.

Add the

Job

to the

Queue

.

4.

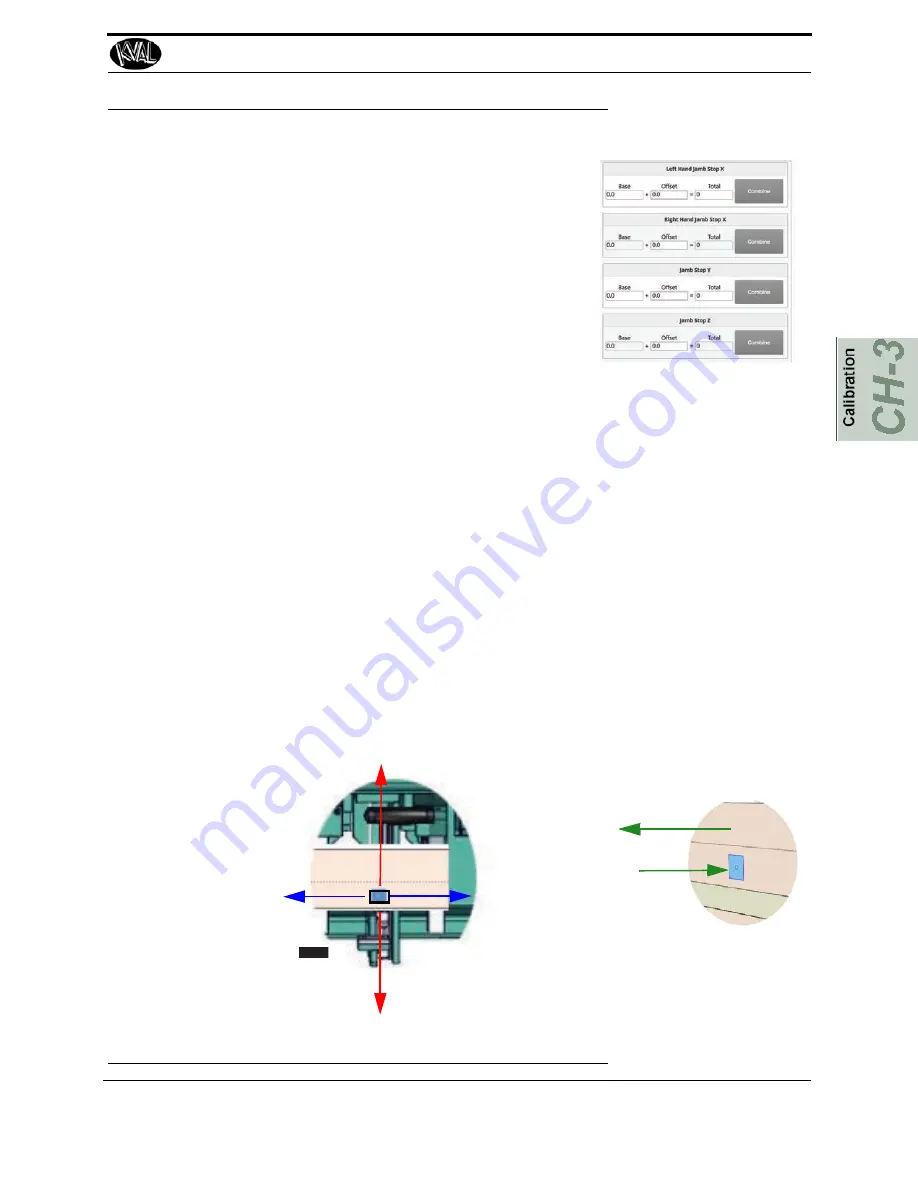

Once the cut has been made, check the location and shape of the cut. See

Figure 3- 4 .

5.

Perform the

Left Hand Rule

from the rear of the machine to determine axis direction.

See illustration below.

• If the location is out of specification in the

length

of the jamb edge, the

X-Axis

needs to be adjusted.

• If the location is out of specification in the

width

of the jamb edge, the

Y-Axis

needs to be adjusted.

• If the plunge cut depth is out of specification, check the

Configuration Menu

then

verify the

Z-Axis.

• If the shape is out specification, adjust for the best location then check the tool

calibrations.

FIGURE 3- 4.

Procedure to Calibrate a Stop

Reference from back of

machine. Point down to the cut

using left hand rule.

+

X

+

Y

+

Z

-

X

-

Y

-

Z

Summary of Contents for 965X

Page 103: ......