Step 3: Calibrate the Tools

3-13

965X Operation Manual

Calibration Reference Cut

The figure below, shows a sample reference cut and the type of offset to input into the calibration

menu.

See “How to Enter Calibration Data” on page 3-6 .

Note:

To help isolate tool function, use the

Tool Config

page to disable or enable sus

-

pected tools. After isolating the tool, run the

Door Job

.

See “Routers: How to Iso

-

late and Calibrate a Specific Router” on page 3-18

Process to Calibrate the Tools

Important:

It is recommended to

verify the Tool Config

settings before calibrating the

plunge cut (

Z-Axis

). This is a global calibration. Therefore, by calibrating,

other tools may be out of calibration. For directions on how to use the con

-

figuration menus,

See “About the Tool Config Tabs” on page 2-29 .

To help

identify tools that need to be calibrated, view

Tool Path Review

.

See “About

the Tool Path Preview Test Screen” on page 2-32 .

1.

Create a

Door Job

of a

Cut

of your choice. The example in this section is a jamb cut

with a plunge and lock plate at a depth of 0.25”.

2.

Add

Door Job

to the

Queue

.

3.

Once the cut is machined, measure the

length

,

width

, and

depth

positions of the cut. If

the cut is not in the specification, determine which tool and axis needs to be cali

-

brated.

4.

Perform the

Left Hand Rule

pointed at the cut lock to determine axis direction. The

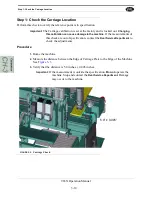

figure below shows a Lock cut on the jamb.

• If

diameters

of the plunges are out of specification, the

Diameter Offset

needs to be

adjusted.

• If the

length

of the cut is out of specification, the

X-Axis

needs to be adjusted.

• If the

width

of the cut is out of specification, the

Y-Axis

needs to be adjusted.

• If the

depth

cut is out of specification, the

Z-Axis

needs to be adjusted.

• If the

corners

of the lock cut are out of specification, the

Chisels Offsets (n

eeds to

be adjusted.

See “Sample Calibration Chisels Cut” on page 3-17.

FIGURE 3- 6.

Axis Location Reference

Summary of Contents for 965X

Page 103: ......