Lubrication Requirements

3-14

965X Service Manual

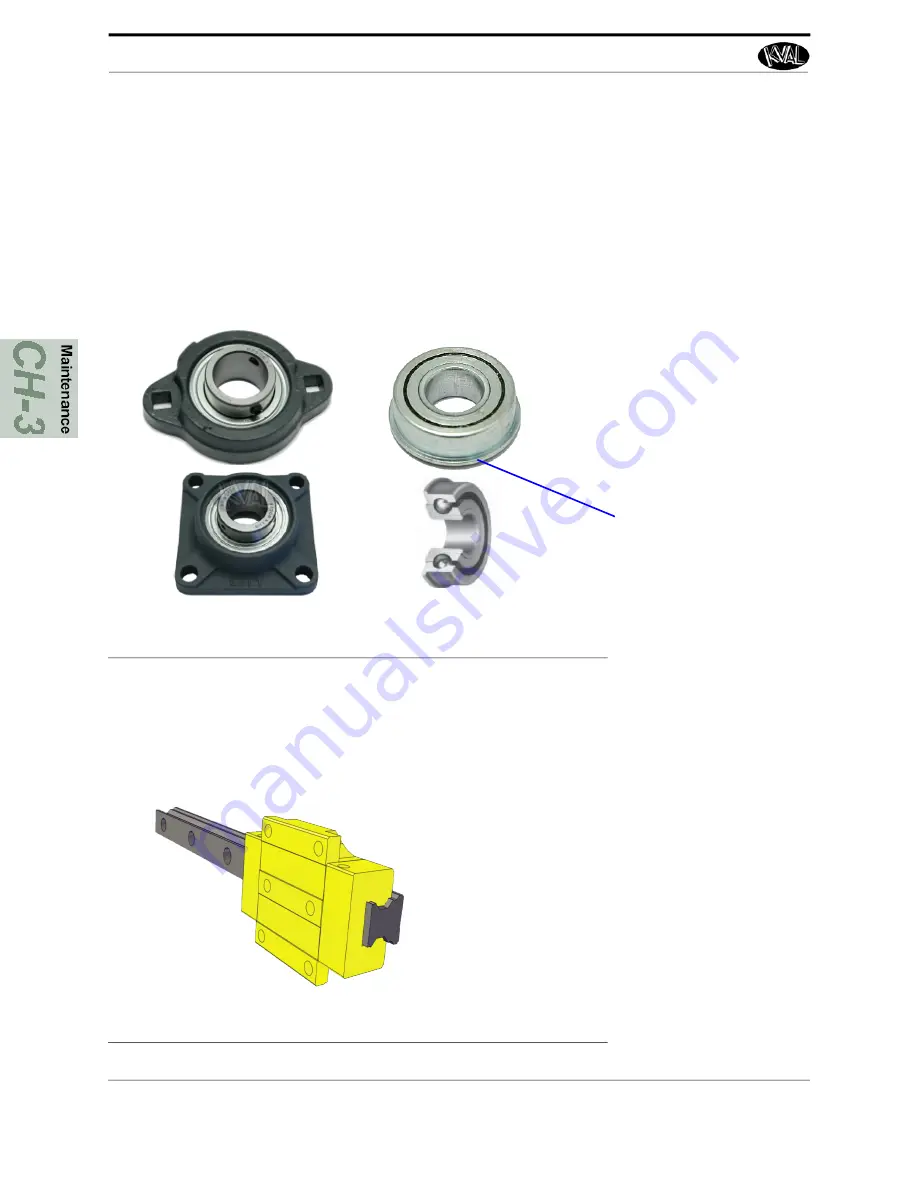

Flange Bearing Housings

A flange bearing is designed to aid in mounting and positioning. The lip of the flange helps center

and align the bearing.

Flanges are also used with bearings on external housings used to mount a bearing unit. A mounted

bearing unit acts as a system to position the bearing securely for reliable operation.

FIGURE 3- 5.

Flange Bearings

Ball Rail Bearing

Ball Rail Bearings

are linear bearings that are attached to positioning rails. In most cases, the bear

-

ings are attached to assemblies to move them in the X,Y, or Z direction.

FIGURE 3- 6.

Ball Rail Bearings

Greasing

Flange

Bearing

Bearing

Housings

Approximatively 1 Gram (one

pump from grease gun) of Dura-

Lith Grease (KVAL P/N: Lube

EP

-

2). Every 250 hours of oper

-

ation.

Lip

Greasing

Ball Rail

Bearing

Approximatively 1 Gram

(one pump from grease gun)

of Dura-Lith Grease

(KVAL P/

N: Lube EP

-

2).

Every 250 hours

of operation

.