Replacing Bits

5-14

KVAL 990-HB Operation / Service Manual

7.

Inspect and verify the work. Clean the work area.

8.

If maintenance is completed, replace dust cover and tighten bolts.

Remove and Replace the Chisels

After lockout tagout and access has been obtained to the assemblies, follow these

instructions to remove and replace the chisels

1.

Ensure air pressure is turned off and pull back the head to get better access to the

chisel assemblies.

2.

Use a 7/16 “wrench to loosen and remove the bracket bolts (2 per chisel) that secure

the chisels.

3.

Remove the bracket.

Note:

The bracket has a tight tolerance and is a tight fit. You may have to use channel

grips to remove the bracket.

4.

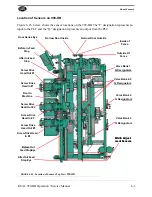

Slide out

Chisel

Remove Bolts with a

7/16 “wrench

Bracket

Orientation

of Chisel

Slide the old chisel out of the assembly. Note the orientation of the chisel

FIGURE5- 24.

Replacing the Chisels

5.

Slide in the new chisels.

6.

Tighten bolts back and forth until the bracket is tight.

7.

Inspect and verify the work. Clean the work area.

8.

If maintenance is completed, replace dust cover and tighten bolts.

Remove and Replace the Screwdriver Bits

To replace screwdriver bits on the Six-Shooter heads, follow the instructions below.

1.

Turn off all power to the machine. Follow proper lockout/tagout procedures as

detailed in the safety section of Chapter 1 of this manual.

Summary of Contents for 990-HB

Page 4: ...KVAL 990 HB Operation Manual ...

Page 25: ...Safety Sign Off Sheet 1 17 KVAL 990 HB Operation Service Manual ...

Page 26: ...Safety Sign Off Sheet 1 18 KVAL 990 HB Operation Service Manual ...

Page 66: ...Diagnostic Screen 2 40 KVAL 990 HB Operation Service Manual ...

Page 84: ...Calibration of the Back Section 3 18 KVAL 990 HB Operation Service Manual ...

Page 88: ...System IT Administration 4 4 KVAL 990 HB Operation Service Manual ...