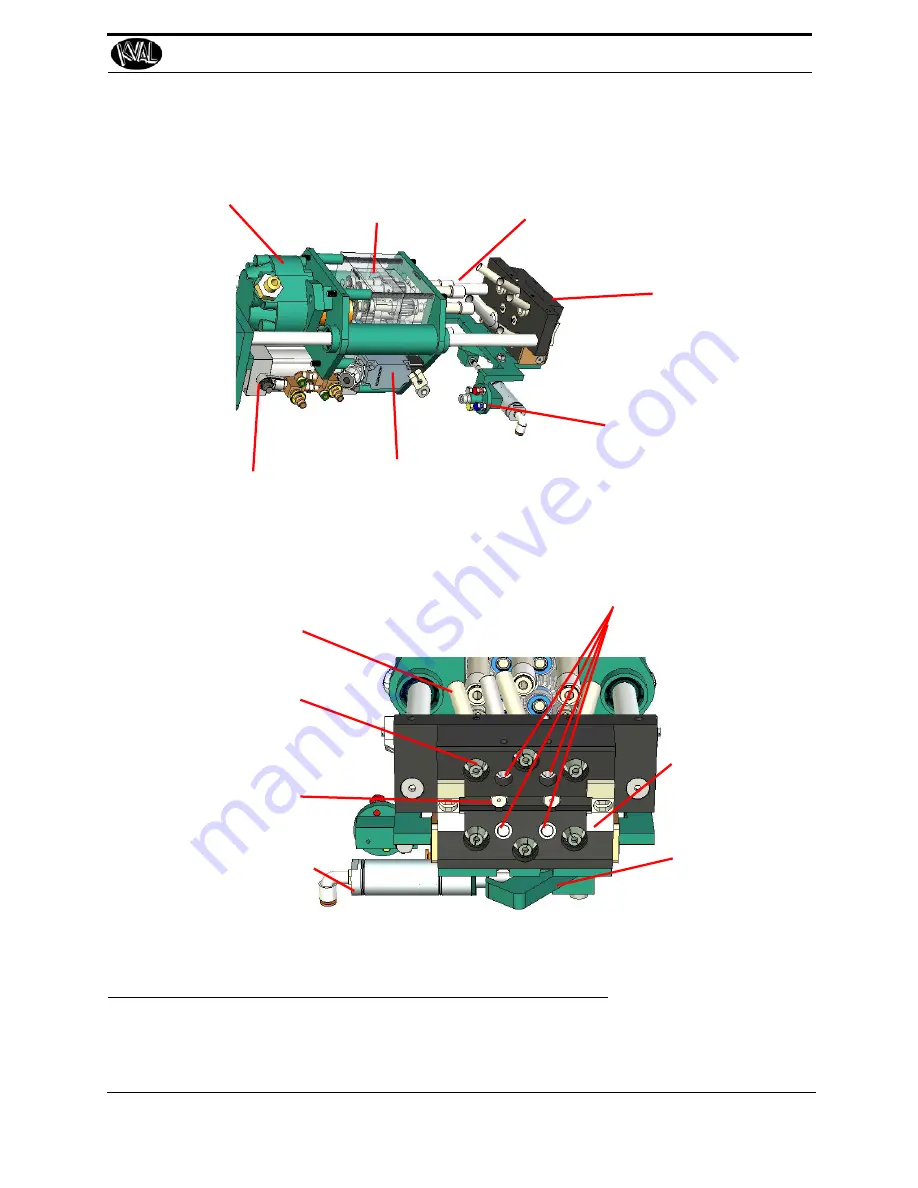

Split Shells X6:

Receives 6 screws, straight-

ens, and aligns them.

Hinge Indexer X2:

Factory set to align

hinge.

Magnets:

Four Magnets hold Hinge

for Application.

Index Spacers X2:

Factory set to align hinge.

Screw Receiver Tubes:

These tubes receive the

screws from the hopper by

way of plastic tubes

Latch Arm:

Latches to H Block

to secure in place.

Latch Arm Cylinder:

Moves latch arm in and out

of position

Air Motor

Gearbox:

Geared to drive 6

screws simultane-

ously

Chucks X6:

Holds 6 screws

aligned to the Door

and the Jamb.

Hinge Applicator:

Location to attach

Hinge

Turret to Adjust Depth:

Adjustable stops to set

the depth of the screw

drivers. Used with the

Forward Limit Switch.

*

Forward Stop

Limit Switch

*

Reverse Stop Limit on

other side

Plunge Cylinder:

Moves the screw

drivers into place

Operator’s Tour

2-9

KVAL 990-HB Operation / Service Manual

FIGURE 2- 7.

Six Shooter and Gear Box Call-Outs

Summary of Contents for 990-HB

Page 4: ...KVAL 990 HB Operation Manual ...

Page 25: ...Safety Sign Off Sheet 1 17 KVAL 990 HB Operation Service Manual ...

Page 26: ...Safety Sign Off Sheet 1 18 KVAL 990 HB Operation Service Manual ...

Page 66: ...Diagnostic Screen 2 40 KVAL 990 HB Operation Service Manual ...

Page 84: ...Calibration of the Back Section 3 18 KVAL 990 HB Operation Service Manual ...

Page 88: ...System IT Administration 4 4 KVAL 990 HB Operation Service Manual ...