Check Specifications of the Front Section

3-7

KVAL 990-HB Operation / Service Manual

Check Specifications of the Front Section

Follow these steps in this section to verify the result of the cut and, if necessary, adjust the

machine.

General Instructions to Adjust Parameters

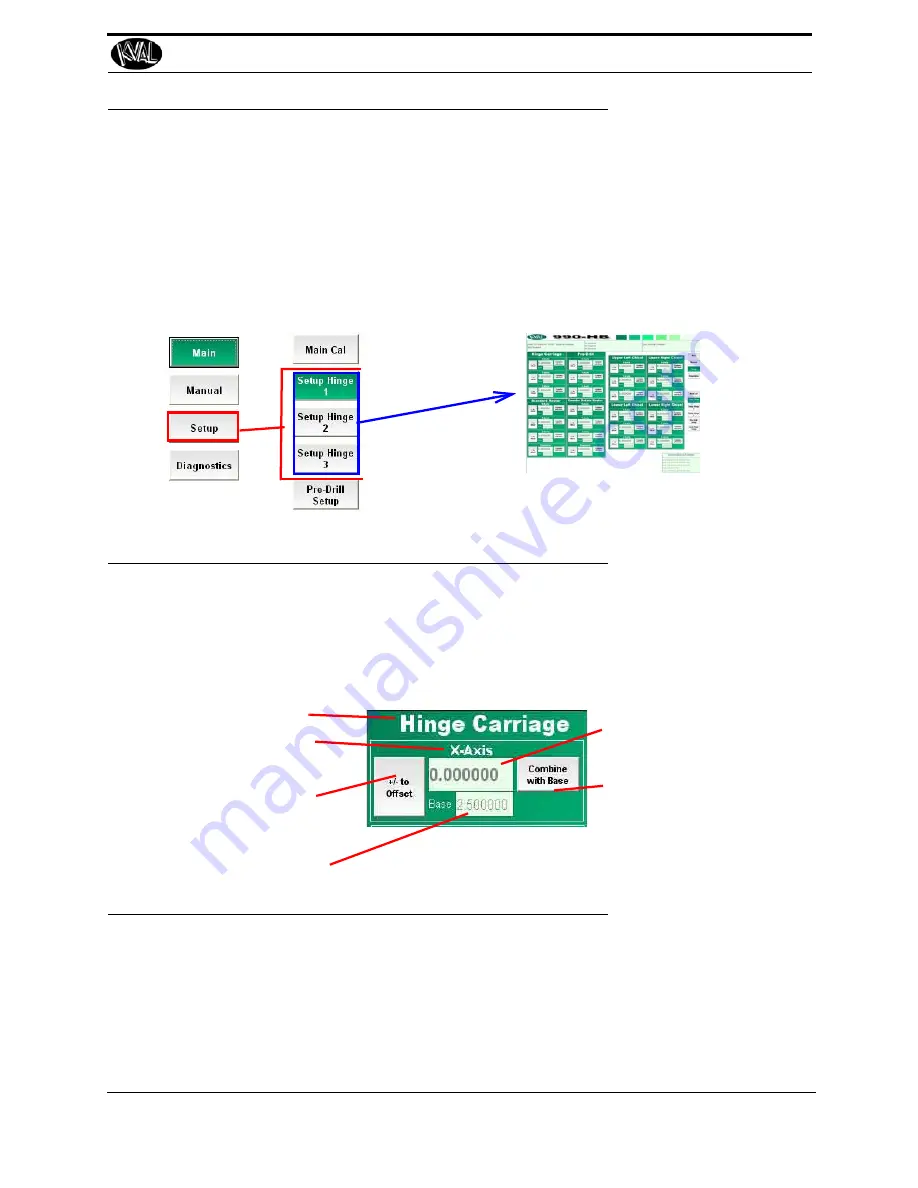

From the Main Screen select

Setup

---

Setup Hinge 1. 2,

or

3

to get to the Hinge Setup screens.See

“About the Setup Hinges 1-3 Screens” on page 2-30 , for further detail.

FIGURE3- 4.

Path to Setup Hinge Screens

Located in the setup screens are adjustment menus. In these menus you can add negative or posi-

tive adjustments to move a cutting assembly to the desired position. Enter the data in the white

box below the parameter. The

Base

display box keeps a running total of data entered to help keep

track of the changes. The

Combine with Base

button stores data in memory and should be used at

first to set a reference and at final to store data.

Title:

of assembly to adjust

Parameter:

to adjust (X,Y,and or Z

axis.)

Offset:

Select this button to add or

subtract the measured number

entered.

Base:

Keeps a Running Total of

measured numbers entered.

Enter:

Type in

measured

data

Combine Base:

Select this

button at

start

of adjustment

to set a reference and

end

of adjustment to store it.

FIGURE3- 5.

Sample of Adjustment Menu

Note:

KVAL suggests to follow the steps in the order below.

Step 1 Verify and Adjust the Hinge Carriage

Step 2 Verify and Adjust the Router Calibration

Step 3 Verify and Adjust the Pre-Drill Calibration

Step 4 Verify and Adjust the Chisel Calibration

Summary of Contents for 990-HB

Page 4: ...KVAL 990 HB Operation Manual ...

Page 25: ...Safety Sign Off Sheet 1 17 KVAL 990 HB Operation Service Manual ...

Page 26: ...Safety Sign Off Sheet 1 18 KVAL 990 HB Operation Service Manual ...

Page 66: ...Diagnostic Screen 2 40 KVAL 990 HB Operation Service Manual ...

Page 84: ...Calibration of the Back Section 3 18 KVAL 990 HB Operation Service Manual ...

Page 88: ...System IT Administration 4 4 KVAL 990 HB Operation Service Manual ...