Check Specifications of the Front Section

3-10

KVAL 990-HB Operation / Service Manual

11.

If slot is not centered, repeat the steps above until the slot is centered.

12.

After centering is achieved, select

Combine with Base

to store the corrections.

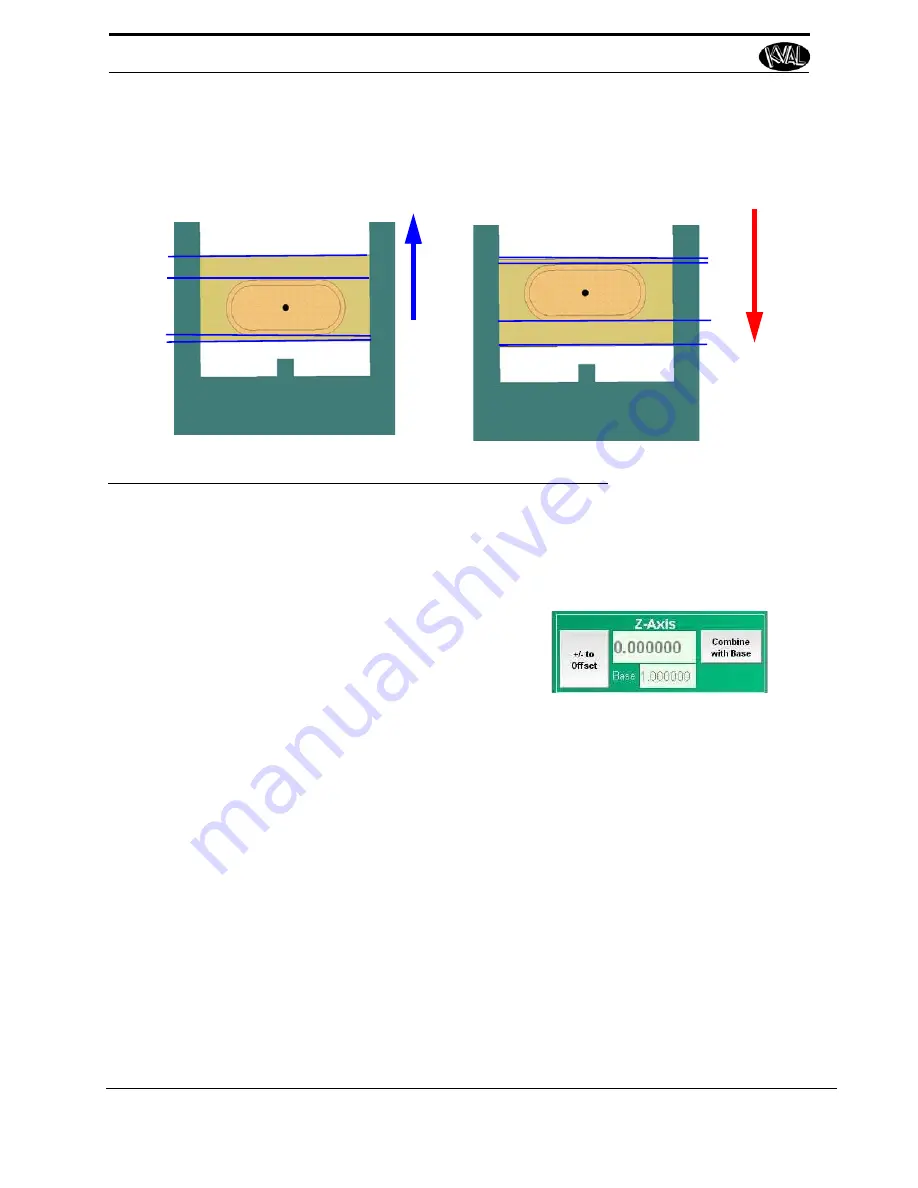

Enter a

positive

number to move the Carriage

Up

Enter a

negative

number to move the Carriage

Down

a

b

a

b

FIGURE3- 7.

Adjusting the Z Axis

1.

Run the Calibration Routine. See “Run the Calibration Routine” on page 3-6.

2.

Measure the depths of the Router and Pre-Drill.

3.

If depths are off, go to the Setup screen and

select the appropriate Z menu

4.

If the depth is too deep, enter a negative number of the difference of the measured

and the desired depth.

5.

If the depth is too shallow, enter a positive number of the difference of the measured

and the desired depth.

6.

Rerun tests until the correct depth is achieved.

Step 2: Router Calibration

Once the Hinge Carriage is calibrated to the center, verify the Router.

• The depth of the router should = 0.050" deep.

• The length of the router should =1.500'' + the diameter of the bit.

• The width should = the diameter of the bit.

• The slot should be centered in the H-block and center on the thickness of the door.

Adjusting the Router:

1.

Run the Calibration Routine. See “Run the Calibration Routine” on page 3-6.

Summary of Contents for 990-HB

Page 4: ...KVAL 990 HB Operation Manual ...

Page 25: ...Safety Sign Off Sheet 1 17 KVAL 990 HB Operation Service Manual ...

Page 26: ...Safety Sign Off Sheet 1 18 KVAL 990 HB Operation Service Manual ...

Page 66: ...Diagnostic Screen 2 40 KVAL 990 HB Operation Service Manual ...

Page 84: ...Calibration of the Back Section 3 18 KVAL 990 HB Operation Service Manual ...

Page 88: ...System IT Administration 4 4 KVAL 990 HB Operation Service Manual ...