Maintenance Schedule

5-3

KVAL 990-HB Operation / Service Manual

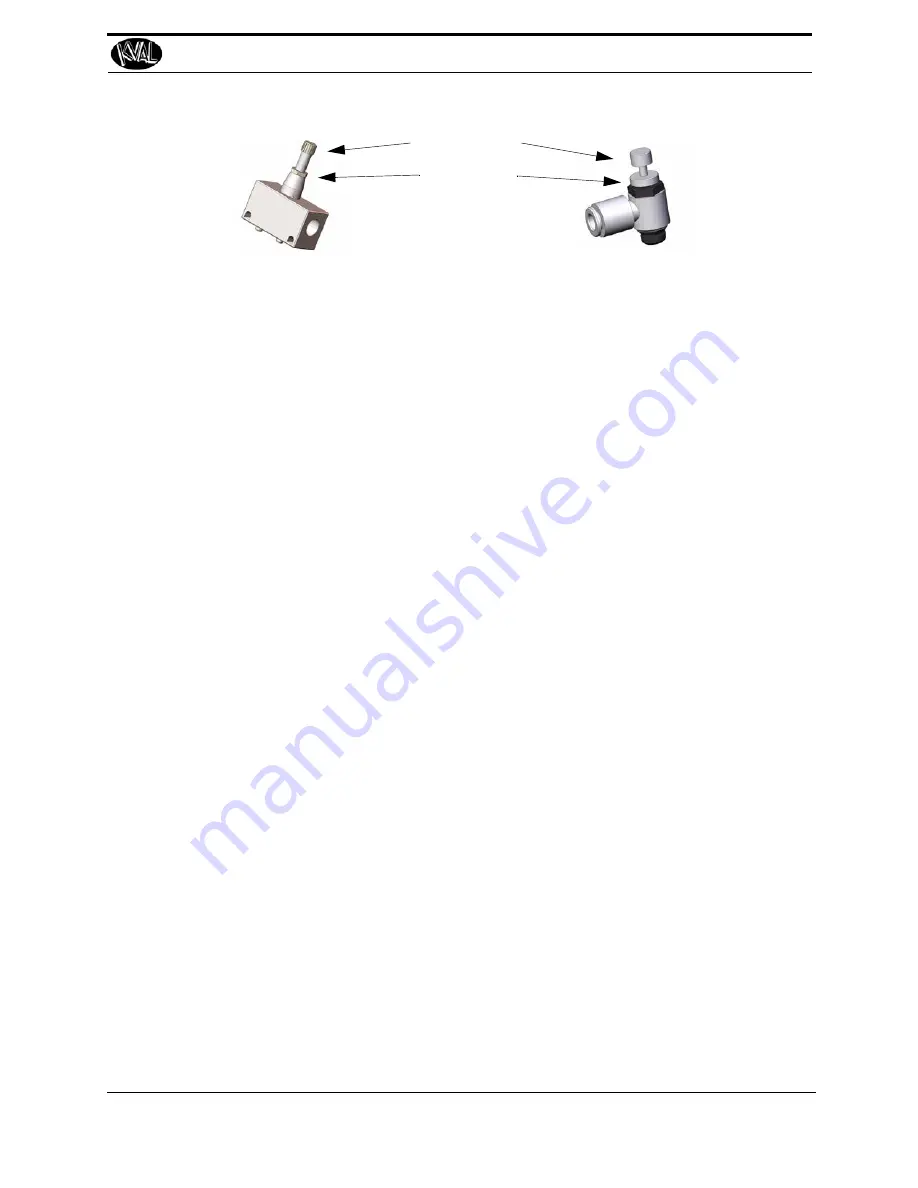

• Inspect lock flow controls. Adjust if required.

Adjustment knob

Tightening nut

• Check all air lines & electrical wiring for kinks or rubbing.

• Refill lubricator with an ISO 32 standard hydraulic oil (use KVAL part# SYS-

LUBEG

Six Month Checkups

• Wash filter and lubricator bowls with soapy water.

• Grease all bearings and tighten all bolts. Access to some grease fittings is difficult

and will require a special needle point grease tip (supplied with your system).

• Clean and lubricate all slides and cylinder rods with dry silicone spray.

• Tighten all bolts.

• Backup computer software. See “Backing up the Computer” on page 3-3.

• Lubricate linear bearings and chrome shafts with silicone

Summary of Contents for 990-HB

Page 4: ...KVAL 990 HB Operation Manual ...

Page 25: ...Safety Sign Off Sheet 1 17 KVAL 990 HB Operation Service Manual ...

Page 26: ...Safety Sign Off Sheet 1 18 KVAL 990 HB Operation Service Manual ...

Page 66: ...Diagnostic Screen 2 40 KVAL 990 HB Operation Service Manual ...

Page 84: ...Calibration of the Back Section 3 18 KVAL 990 HB Operation Service Manual ...

Page 88: ...System IT Administration 4 4 KVAL 990 HB Operation Service Manual ...