Maintenance Schedule

5-2

KVAL 990-HB Operation / Service Manual

Maintenance Schedule

KVAL recommends the following maintenance schedule to ensure that the machine operates

properly. Refer to this section for steps to perform maintenance.

TABLE 5-1.

Recommended Lubrication Schedule

Type of Assembly

Recommended Schedule

Recommended Lubrication Type

Linear Bearing

Every 250 Hours of Machine Operation

Dura-Lith Grease (KVAL P/N Lube EP-2)

Pillow Block Bearing

Flange Block Bearing

Ball Screw

Every 80 Hours of Machine Operation

Air Line Lubricator

One drop of oil every 2 or 3 cycles

Check the lines every week to two weeks

Either lubricant listed below is approved to

use.

• KVAL

P/N

SYSLUBG

•

Chevron AW Hydraulic Oil 32

•

G-C lubricants light AW R&O

•

Mobile DTE 24

• Shell

Tellus32

•

Gulf Harmony 32

Gear Box

2000 Hours of Machine Operation or six months

of operation

•

AGMA #8 gear lube

•

MOBILUBE HD 80 W-90

• or

equivalent

Daily

• Blow off dust from the entire machine.Wipe down the outside of the machine with a

clean dry cloth

• .Check tooling for wear.

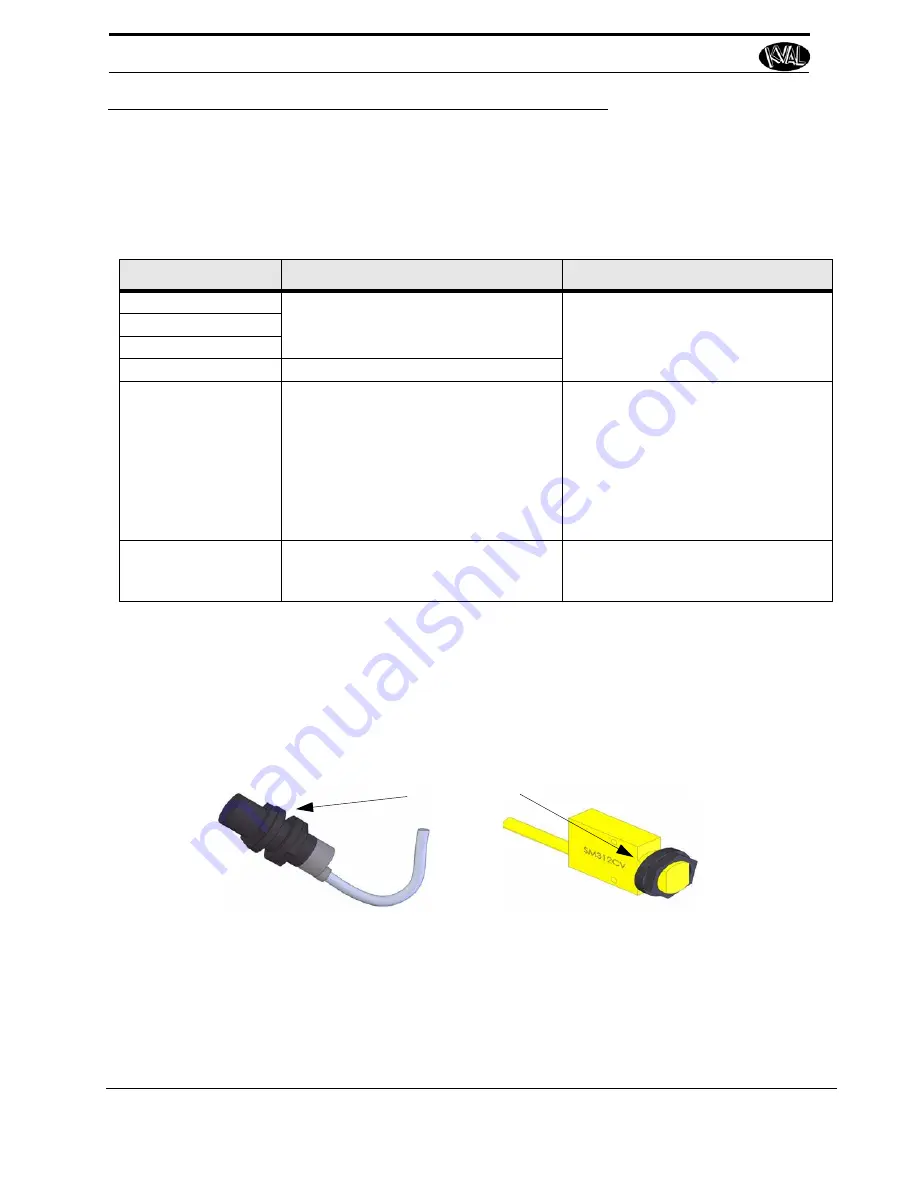

• Wipe off the photo eyes with a clean dry cloth, and check to ensure that all fastening

nuts are snug.

CAUTION

: Fastening nuts (as well as eyes) are plastic and threads can strip easily.

Fastening Nuts

• Check the air pressure to make sure it is set at 80 psi to100 psi.

• Check the air filter water trap. Empty it, if it is full.

Weekly

• Check the machine for smooth motion through a complete door cycle.

• Clean linear bearings and the chrome shaft with a clean dry cloth, then lubricate.

Summary of Contents for 990-HB

Page 4: ...KVAL 990 HB Operation Manual ...

Page 25: ...Safety Sign Off Sheet 1 17 KVAL 990 HB Operation Service Manual ...

Page 26: ...Safety Sign Off Sheet 1 18 KVAL 990 HB Operation Service Manual ...

Page 66: ...Diagnostic Screen 2 40 KVAL 990 HB Operation Service Manual ...

Page 84: ...Calibration of the Back Section 3 18 KVAL 990 HB Operation Service Manual ...

Page 88: ...System IT Administration 4 4 KVAL 990 HB Operation Service Manual ...