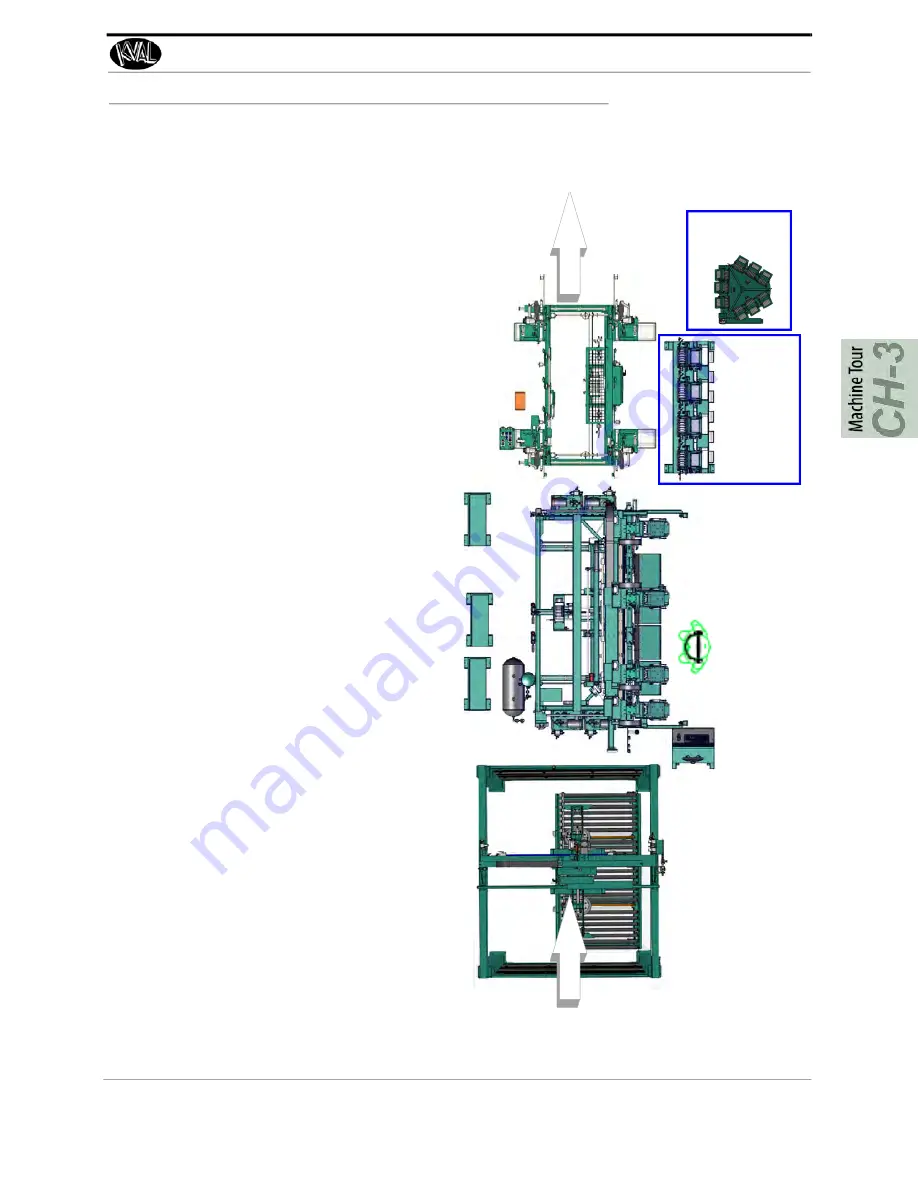

Common 990-FX Line Layout

3-3

KVAL 990-FX Operation Manual

Common 990-FX Line Layout

Below a common line layout of

990-FX

with an array hopper system.

The 990-FX:

• Cut a hinge pocket on a door and jamb for up

to three hinges (Head Assembly)

• Drill pilot holes for the hinge screws (Head

Assembly)

• Choose different screws by way of the Hop

-

pers. (Array, On Machine, or RTS-FX)

• Apply up to four hinges.(Six Shooter)

• Attach the hinges with screws (Six Shooter)

• Cut a lock and lock plate (Back Section)

• Is Controlled by a Central Operators Station

The Feeder:

• Automatically lifts a door from a stack in the

staging area

• The door is placed onto the powered roller

• )The door is fed into the

990-FX

automatically

or with a call door function.

• After the door is fed into the

990-FX

the action

is repeated

• For a detailed description of the Feeder, see

the Feeder Operation/Service Manual

Note:

Feeders may vary, common Feeders are the

ON-3 series the Handler series.

The 700 C:

• IA strike jamb and Header are placed into the

machine.

• A processed door is fed in from the

990-FX

• The door with the hinge jamb is gently lowered

into place.

• The door, header and strike jambs are clamped

by way to a foot pedal

• The foot pedal activates programed staple pat

-

terns to attach the jambs to the header.

• The door is fed out for packaging for packaging

• For a detailed description of the 700-C, see the

700-C Reference Manual

Door Path

RTS-FX

Hoppers

Array

Hoppers