Tour of the Machine

3-19

KVAL 990-FX Operation Manual

Hopper Process

1.

Pour Screws into the

Hopper.

Note:

The recommended maximum amount of screws a quantity of 600.

2.

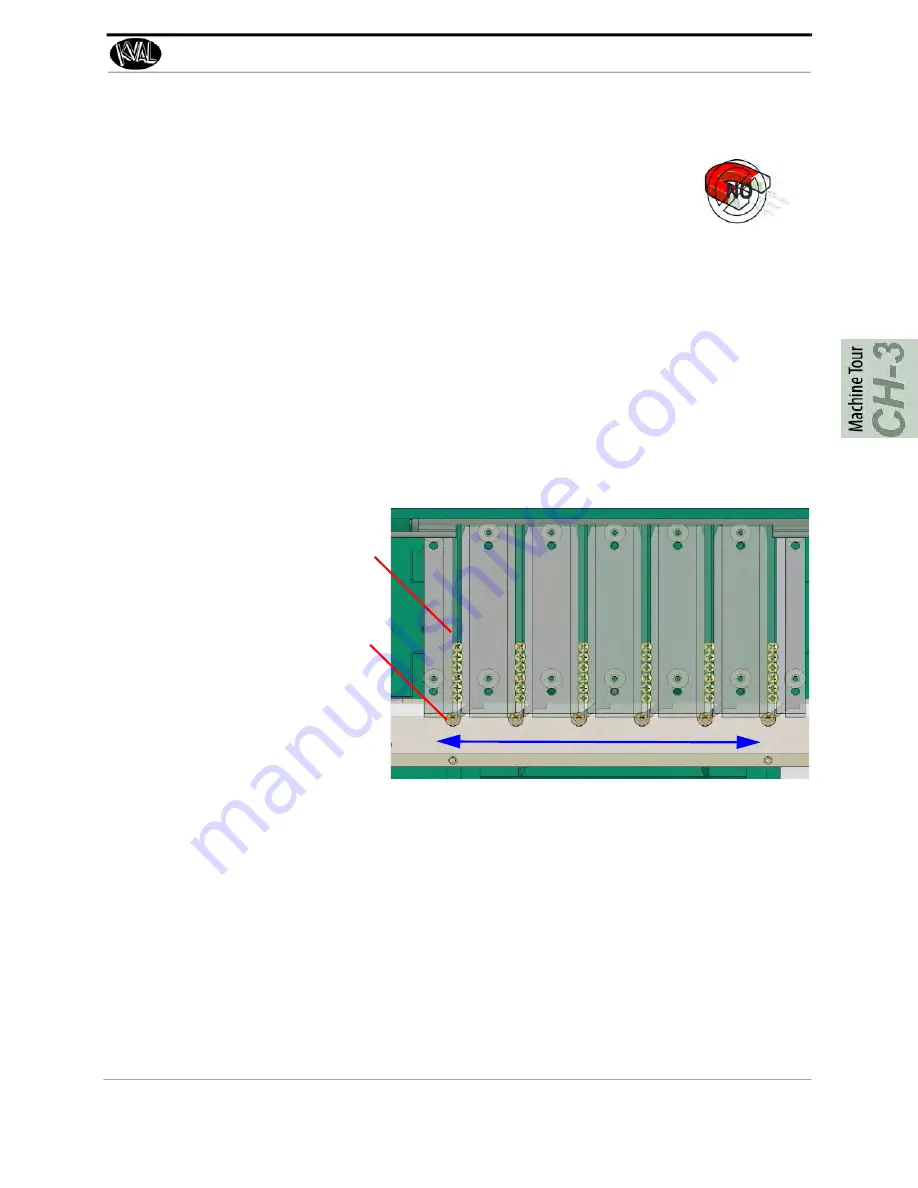

The

Hopper

moves up and down periodically during the process by the

Hopper Cyl

-

inders

to organize the screws and deliver them to the

Screw Tracking Plate

.

3.

The

Gate Assembly

monitors the quantity of screws delivered to the to the

Screw

Tracking Plate Assembly

.

6.

Press

Hinges Loaded

on the Six Shooter Control panel to activate the Slide Assem

-

bly to drop the screws into the

Screw Delivery Tubes.

7.

Each tube has air injectors to speed the delivery to the

Screw Receiver Tubes

.

Quick Change Process

Some Six Shooter Systems have an a quick change option to quickly change to differ

-

ent colored screws. To start the quick change process:

8.

Press the

Load

button on the

Touch Screen

.

The back section of the Hopper will cycle upward once to shift all the screws from

the back door to clear screws between the back door of the hopper and the slides.

9.

Once the Hopper is in the up position, the door will open and the Hopper will cycle

down quickly to throw the surplus of screws out the funnel container.

Important:

Do not put Magnetized Screws in Hopper. Magnetized

screws can cause sluggish response to screws getting

stuck. Hopper plates could get magnetized and will have

to be demagnetized with a degausser.

4.

The screws are stacked

in the slots of the

Screw

Tracking Plate Assem

-

bly

.

5.

The

Screw Pick Off Cyl

-

inder

moves the

Slide

Assembly

to capture

screws six at a time.