Tour of the Machine

KVAL 990-FX Operation Manual

3-20

10.

Once in the back section is in the down position, the front section (

Screw Tracking

Assembly

) moves upward to drain the rest of the screws out of the hopper this will

cycle one more time to clear the screws from the slides.

11.

Press the

Reset

button on the Six Shooter panel located mid machine on the front

section.

12.

Fill the Hopper with new screws.

About the Six Shooter Assembly

Settings for the Six Shooter assemblies are entered in the User Interface. Door is automatically

positioned while the operator loads and clamps a hinge jamb. Routing and boring occur while the

operator places hinges into the nests of the hinge applicators.

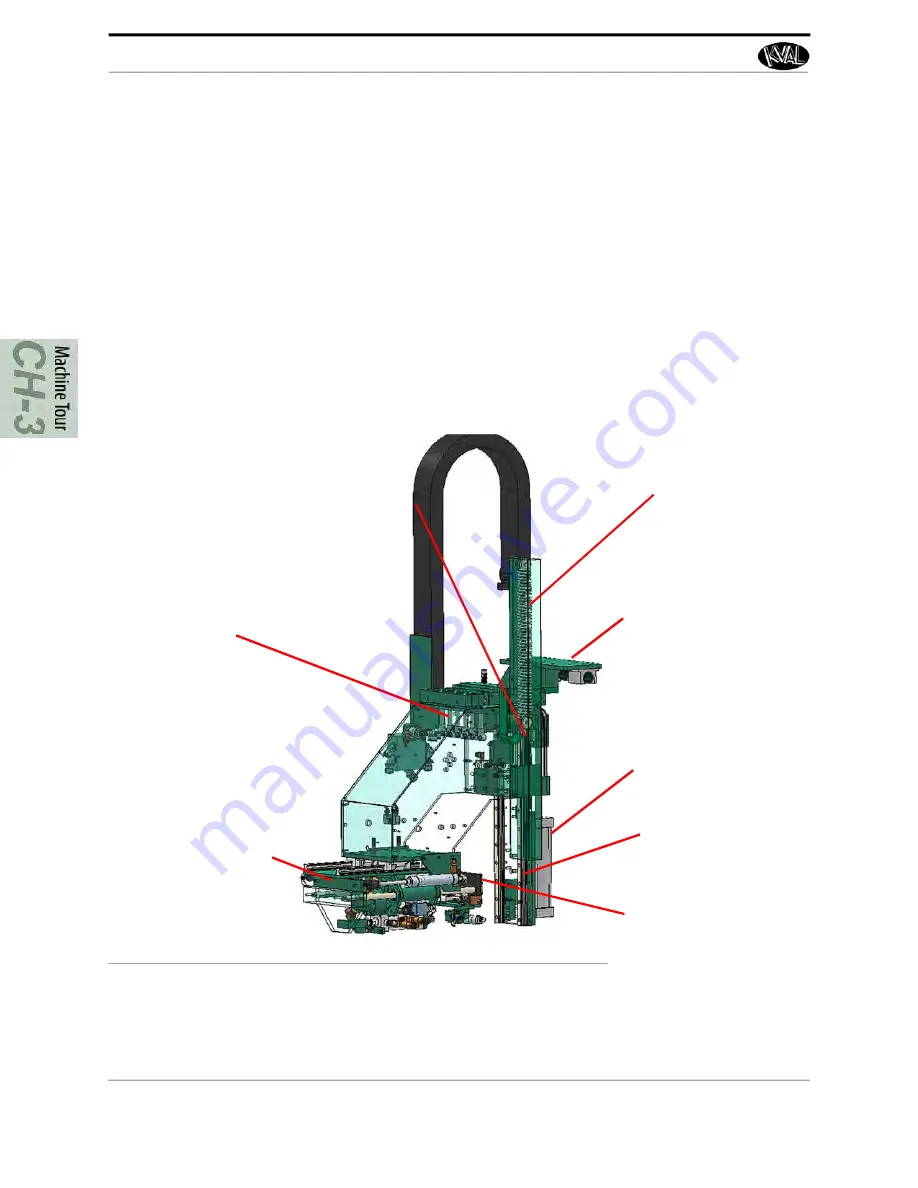

Six Shooter (Hoppers on Machine)

FIGURE 3-12.

Six Shooter Call-Outs Hoppers on machine

Horizontal Rails.

Allows the Six Shooter to

the move to the side for

Maintenance and Manual

application of Hinges

Vertical Rails:

Tubes:

Delivers Screws to Hinge

Applicator by way of plas

-

tic tubes.

Driver Assembly:

Hinge Application:

Vertical Cylinder:

Drives Six Shooter Up

and Down

Spring:

Tension for vertical

movement

Note:

Air brakes are located on the

vertical rails. The brakes will operate

when air pressure goes down a set

reference level.