Check Specifications of the Front Section

KVAL 994-X Operation/Service Manual

3-16

2.

Choose the axis to be calibrated,

a.X (Horizontal)

b.Y (Vertical)

c.Z (Depth)

3.

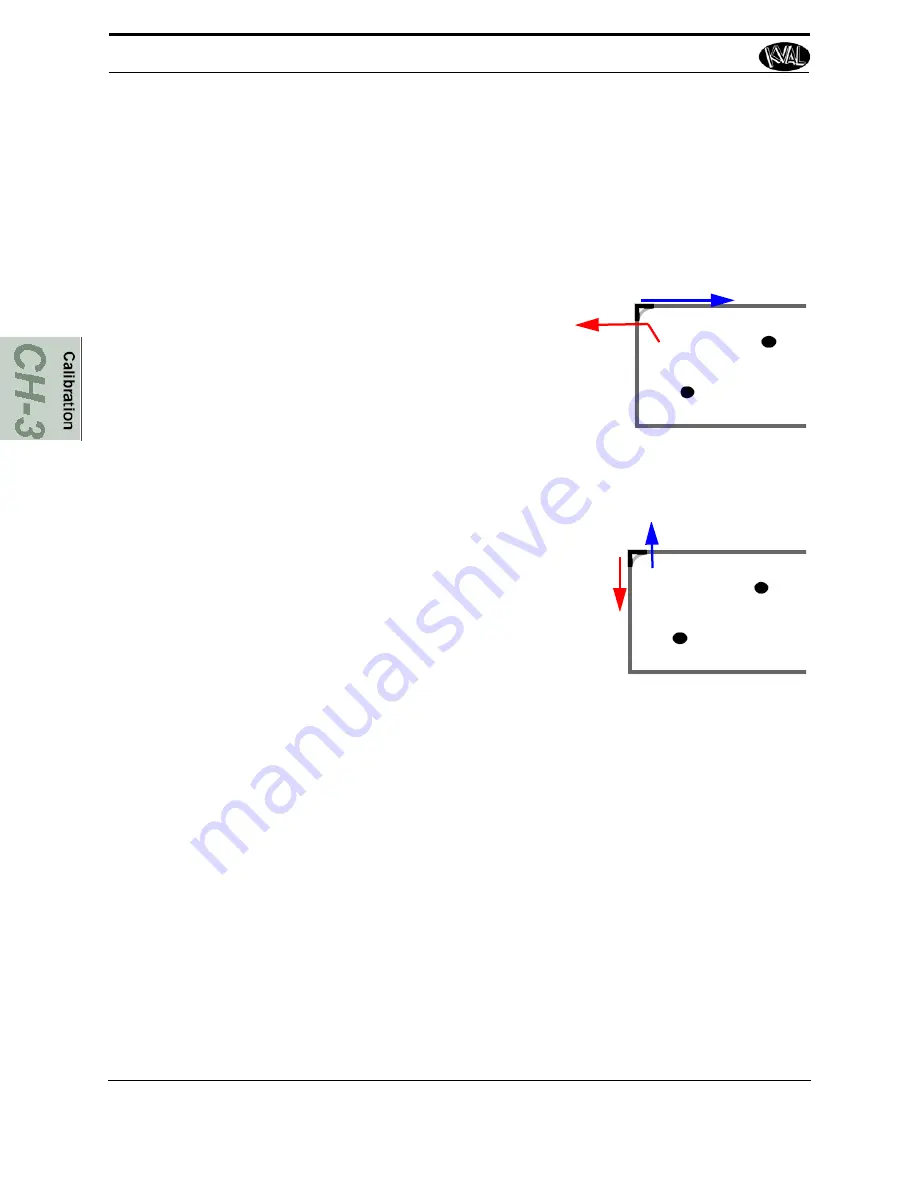

X-Axis:

use a caliper to measure how much the chisel cut is off compared to the ver-

tical hinge cut with the router on the jamb.

a.Take the caliper measurement, and enter it into

the X-axis box.

b.If the chisel needs to move to the left, enter it as

a negative number.

c.If the chisel needs to move to the right, enter a

positive number.

d.Repeat until chisel position is correct.

Positive

Negative

4.

Y-Axis:

use a caliper to measure how much the chisel cut is off compared to the hor-

izontal hinge cut with the router on the jamb.

a.Take the caliper measurement, and enter it into

the Y-axis box.

b.If the chisel needs to move down, enter it as a

negative number.

c.If the chisel needs to move up, enter a positive

number

d.Repeat until chisel position is correct

Positive

Negative

5.

Z-Axis:

use a caliper to measure the depth of the chisel compared to the correspond-

ing hinge route.

a.Take the caliper measurement, and enter it into the Z-axis box.

b.If the chisel is too deep enter it as a negative number.

c.If the chisel is too shallow, enter it as a positive number.

d.Repeat until chisel position is correct

6.

Click the “Combine with Base” button to combine the two numbers to create refer-

ence.

Summary of Contents for 994-X

Page 4: ...KVAL 994 X Operation Service Manual ...

Page 31: ...Safety Sign Off Sheet 1 21 KVAL 994 X Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet KVAL 994 X Operation Service Manual 1 22 ...

Page 110: ...Calibration of the Back Section KVAL 994 X Operation Service Manual 3 22 ...

Page 114: ...System IT Administration KVAL 994 X Operation Service Manual 4 4 ...

Page 144: ...Collet Torque Values KVAL 994 X Operation Service Manual 5 30 ...

Page 180: ...Symptoms and Possible Causes KVAL 994 X Operation Service Manual 6 36 ...

Page 185: ......

Page 186: ......

Page 187: ......