12,000 Cycle Maintenance Steps

5-11

KVAL 994-X Operation/Service Manual

12,000 Cycle Maintenance Steps

Follow Lockout Tagout procedures.

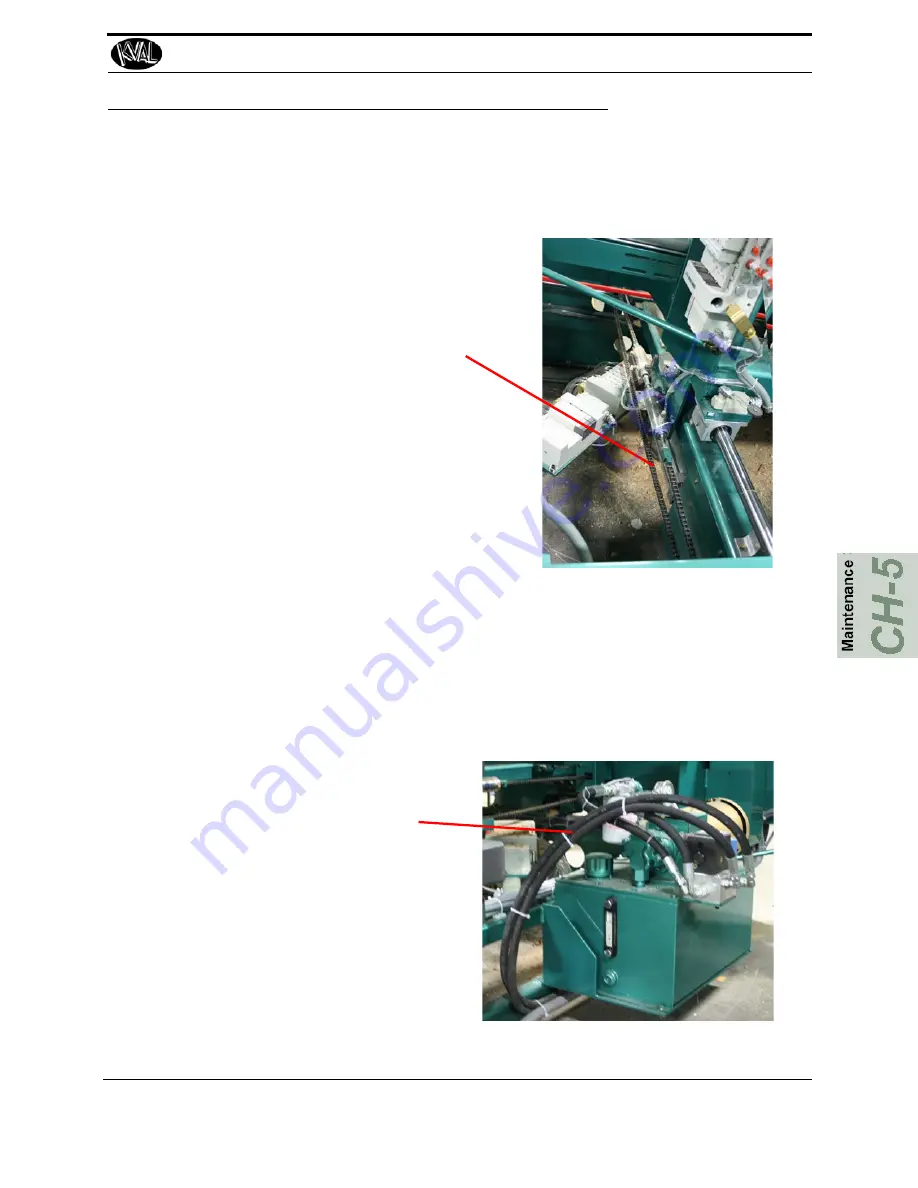

Inspect Chains for Proper Tension

Inspect chains for proper tension or damage.

Check for sagging chains. Chains can stretch

over time of use.

Check for chain stiffness. Stiff chains do not

provide a tight fit over the gears.

Inspect Air Cylinders

Inspect all air cylinders for air leaks. Replace the cylinder if seal is leaking. Symptoms include a

cylinder not extracting or retracting to the limits. Cylinders not holding their position.

Inspect Hydraulic Lines

Inspect hydraulic lines for loose fittings,

leaks and cracks.

Inspect hydraulic lines from the source to

the end assembly.

Summary of Contents for 994-X

Page 4: ...KVAL 994 X Operation Service Manual ...

Page 31: ...Safety Sign Off Sheet 1 21 KVAL 994 X Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet KVAL 994 X Operation Service Manual 1 22 ...

Page 110: ...Calibration of the Back Section KVAL 994 X Operation Service Manual 3 22 ...

Page 114: ...System IT Administration KVAL 994 X Operation Service Manual 4 4 ...

Page 144: ...Collet Torque Values KVAL 994 X Operation Service Manual 5 30 ...

Page 180: ...Symptoms and Possible Causes KVAL 994 X Operation Service Manual 6 36 ...

Page 185: ......

Page 186: ......

Page 187: ......