About the KVAL Calibration Routine

KVAL 994-X Operation/Service Manual

3-4

About the KVAL Calibration Routine

The calibration routine creates a reference cut to check settings against a “known good” source.

The routine is used to verify the front section. It routes a horizontal slot and drills a center hole at

precise specifications. Using these specifications as a reference, you can inspect the pattern and

the specifications of the slot for inaccuracies. The front end assemblies that use the calibration

routine are as follows:

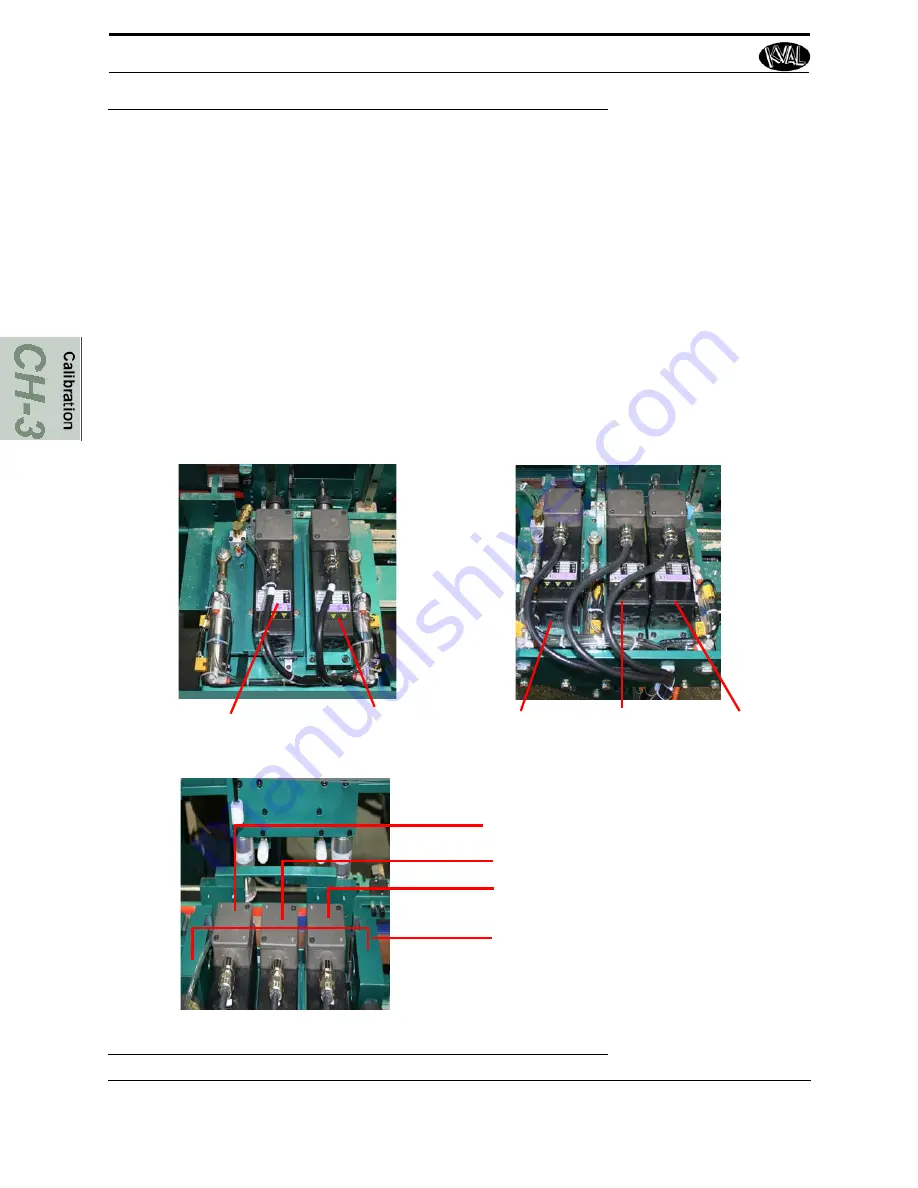

1.

Hinge Carriage

2.

Router (Standard)

3.

Option CR: Counter Rotate Router to eliminate chipouts.

4.

Option CH: Chisels to square the cut

5.

Pre-Drill

Pre-Drill:

Drills pilot holes for

insertion of screws on

the jamb and the door

Router:

Routs the

hinge pocket on the

jamb and the door

Counter Rotate

Router:

Router

minimizes chip outs

on door and Jamb

Pre Drill:

Router:

Standard

Option CR

Standard

Option CH

Counter Rotate Router:

Router:

Standard

Chisels:

Two chisels per assembly. Square

off Jamb and Door hinge cuts.

FIGURE 3- 2.

Location of Assemblies

Summary of Contents for 994-X

Page 4: ...KVAL 994 X Operation Service Manual ...

Page 31: ...Safety Sign Off Sheet 1 21 KVAL 994 X Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet KVAL 994 X Operation Service Manual 1 22 ...

Page 110: ...Calibration of the Back Section KVAL 994 X Operation Service Manual 3 22 ...

Page 114: ...System IT Administration KVAL 994 X Operation Service Manual 4 4 ...

Page 144: ...Collet Torque Values KVAL 994 X Operation Service Manual 5 30 ...

Page 180: ...Symptoms and Possible Causes KVAL 994 X Operation Service Manual 6 36 ...

Page 185: ......

Page 186: ......

Page 187: ......