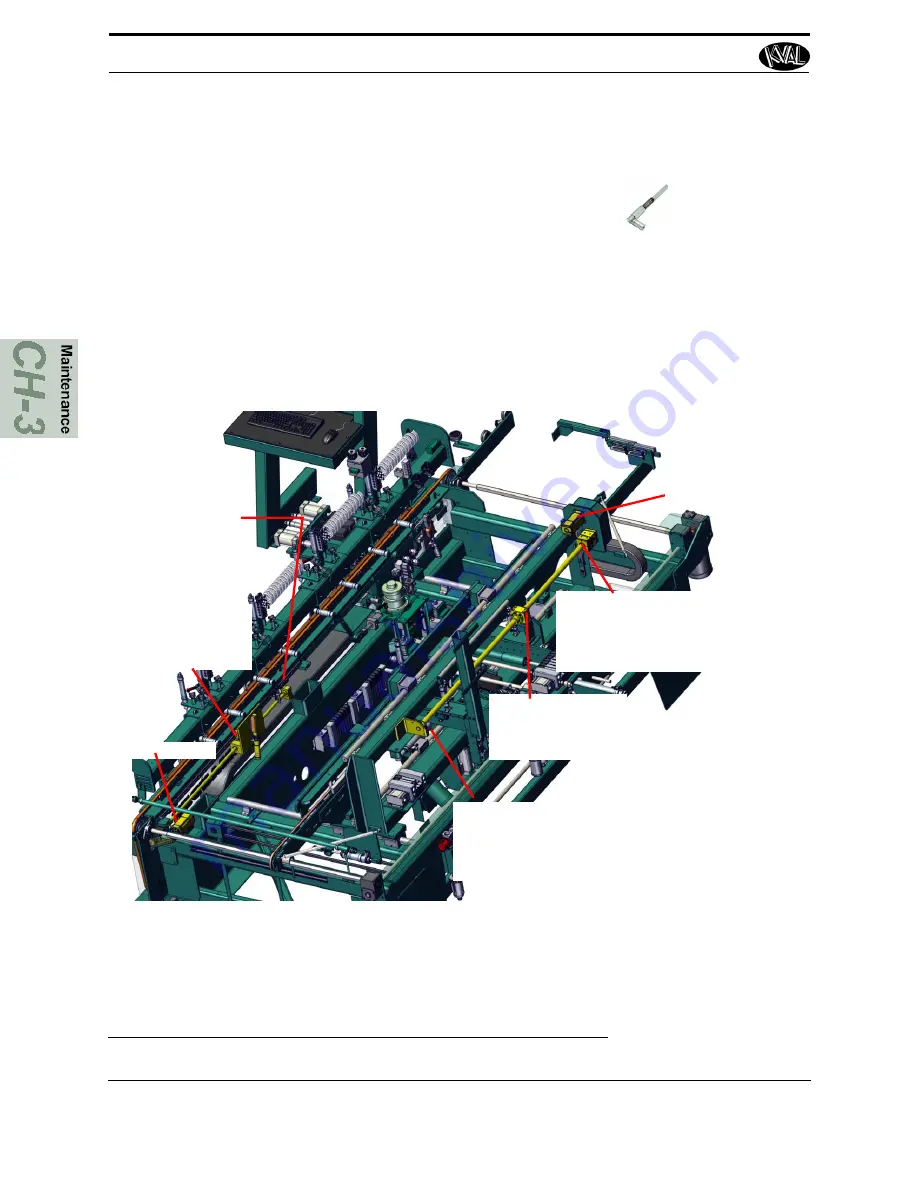

Sample of Grease Locations for the Machine

KVAL Commander III Service Manual

3-22

Servo Grease Locations

Use an extender to reach tight areas. Make sure to

Lockout/Tagout

before maintenance. For rec-

omme

Extension Adapter

Needle Nozzle

It is recommended to use an extension needle in applying grease to the

Outfeed Stop Servo Assembly

grease points

nded lubrication schedule,

see “Lubrication Schedule” on page 3-15.

The Lock Location Servo Assembly is attached to the back section.

The Outfeed Stop Servo Assembly is located at the end of the machine on the inside front sec-

tion.The Assembly is accessed by way of a cut out section on the frame.

FIGURE 3-11.

Servo Motor Assembly Bearings

Tapered Bearing Housing

Recommend One a Pump4 X a

Year Maximum

Pillow Block (Hub

Style

Recommended

every 250 Hrs

Ball Screw Nut

Recommended

every 80 Hrs

Servo Motor

Servo Motor

Pillow Block (Hub

Style

Recommended

every 250 Hrs

Ball Screw Nut

Recommended

every 80 Hrs

Outfeed Stop Servo Assembly

Lock Location Servo Assembly

Summary of Contents for Commander III

Page 5: ...KVAL Commander III Service Manual KVAL Commander III Service Manual ...

Page 10: ...Notes ...

Page 31: ...Safety Sign Off Sheet 1 21 KVAL Commander III Service Manual ...

Page 36: ...Notes ...

Page 75: ...Collet Torque Values 3 39 KVAL Commander III Service Manual ...

Page 76: ...Collet Torque Values KVAL Commander III Service Manual 3 40 ...

Page 100: ...Network System Overview KVAL Commander III Service Manual 4 24 ...

Page 103: ......