About a Typical Pneumatic Circuit

KVAL Commander III Service Manual

4-10

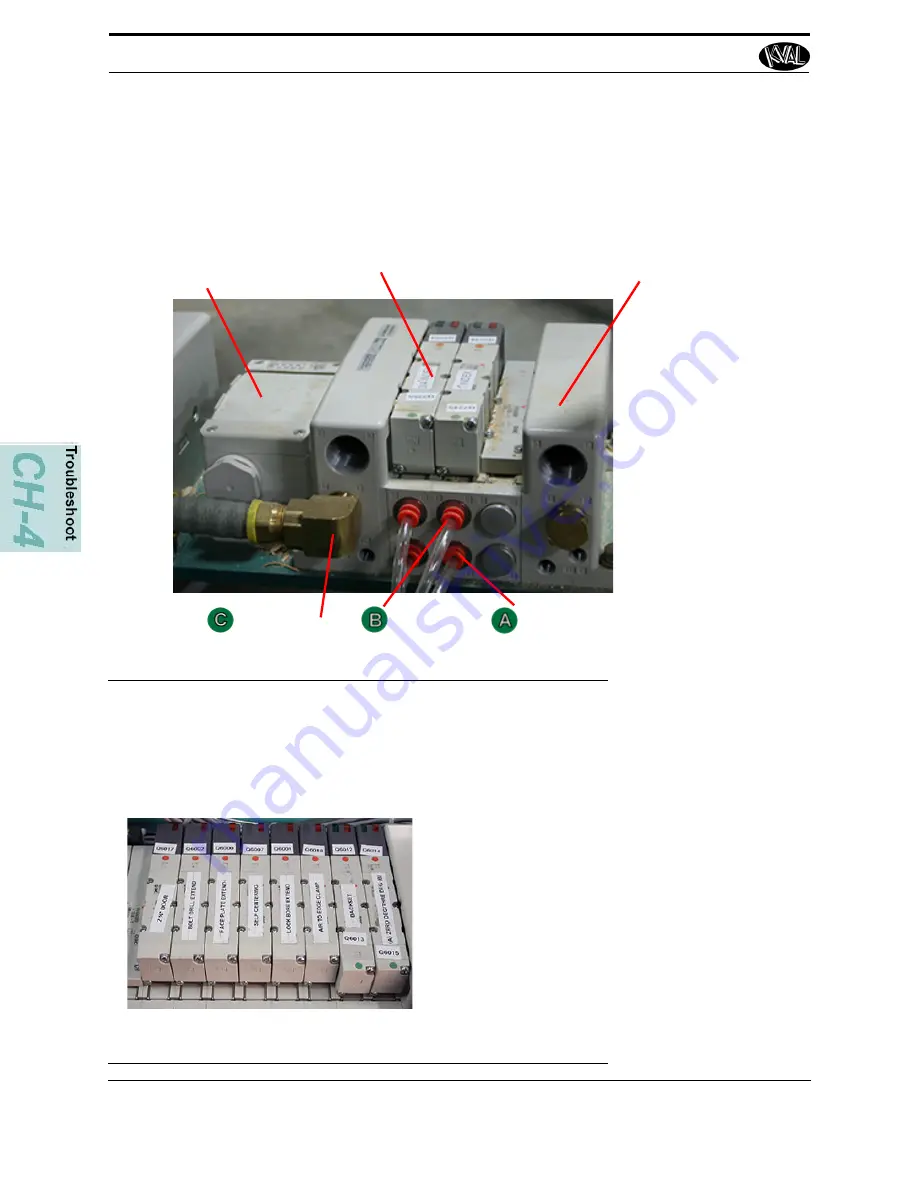

Typical Pneumatic Assembly

Pneumatic assembly setups vary in KVAL machines depending on where it is used and air

requirements.

This is a general overview of a pneumatic assembly

.

See the machine’s Air

Print for detailed information.

FIGURE 4- 31.

Typical Pneumatic Assembly

About the Coil (Solenoid)

The Solenoids are connected to the top of the manifold. Labels indicating their function and PLC

connections are attached to the solenoid body. Use this information to troubleshoot system if nec-

essary.

Solenoid type will vary with machine application.

Common controls include an operational LED and

Manual operation button

Manual Activate Button:

Push to toggle solenoid to the

‘ON’ state. activates if power is off.

Indicator:

a Lit LED indicates the solenoid is in

use.Red LED= the ‘A’ Port on a single valve. If double

valve, Red LED= the ‘A’ Port and Green LED = the ‘B’

port.

FIGURE 4- 32.

Solenoids in Manifold

Air Input

Cylinder

Retract

Cylinder

Extend

Electrical Wiring Box:

Contains inputs from PLC

to Coils (Solenoids)

Manifold:

Base to accept air

input and output air.

Coil (Solenoid):

Receives

input(24V) from PLC to open a port

Summary of Contents for Commander III

Page 5: ...KVAL Commander III Service Manual KVAL Commander III Service Manual ...

Page 10: ...Notes ...

Page 31: ...Safety Sign Off Sheet 1 21 KVAL Commander III Service Manual ...

Page 36: ...Notes ...

Page 75: ...Collet Torque Values 3 39 KVAL Commander III Service Manual ...

Page 76: ...Collet Torque Values KVAL Commander III Service Manual 3 40 ...

Page 100: ...Network System Overview KVAL Commander III Service Manual 4 24 ...

Page 103: ......