Step 5: Calibrate Lock Edge Tools (Option)

KVAL Operation Manual

4-16

Step 5: Calibrate Lock Edge Tools (Option)

This section focuses on the

Edge Tool Calibration

. For instructions about entering calibration data,

see “How to Enter Calibration Data” on page 4-6.

About the Edge Carriage Axis

Do

not

adjust a cut with the

Edge Carriage Axis Calibration

. The calibration is to be used by

trained Service Technicians.

Process to Calibrate the Lock Edge Tool

1.

Create a

Door Job

of a

Lock Cut

of your choice

2.

Add

Door Job

to the

Queue

.

3.

Once the cut is machined, measure the

length

,

width

, and

depth

positions of the cut.

If the cut is not in the specification, determine which axes need to be calibrated.

4.

Perform the

Left Hand Rule

pointed at the cut lock to determine axis direction. See

illustration below.

• If the

length

position of the lock cut is out of specification, the

X-Axis

needs to be

adjusted.

• If the

width

position of the lock cut is out of specification, the

Y-Axis

needs to be

adjusted.

• If the

depth

cut is out of specification, the

Z-Axis

needs to be adjusted.

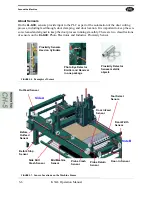

To determine axis direction.

Stand at the Lock Side of Door, point at the lock edge of the door with the left hand rule.

+

X

+

Z

-

X

-

Y

-

Z

+

Y

Summary of Contents for DL-NCD

Page 10: ...KVAL DL NCD Operation Manual Table of Contents ...

Page 28: ...How to Download the Service Application KVAL Operation Manual 1 18 ...

Page 30: ...Safety Sign Off Sheet KVAL Operation Manual 1 20 ...

Page 62: ...About the LiteCutout Feature Detail KVAL Operation Manual 2 32 ...

Page 94: ...Appendix About Backing up the Data KVAL Operation Manual 3 32 ...

Page 118: ...Appendix Servo Motor Drive Assembly Locations KVAL Operation Manual 4 24 ...

Page 139: ...About the Electrical Panels KVAL Operation Manual 5 21 I ...

Page 142: ......

Page 143: ......