About the Tool Config Tabs

KVAL Operation Manual

3-22

About the Tool Config Tabs

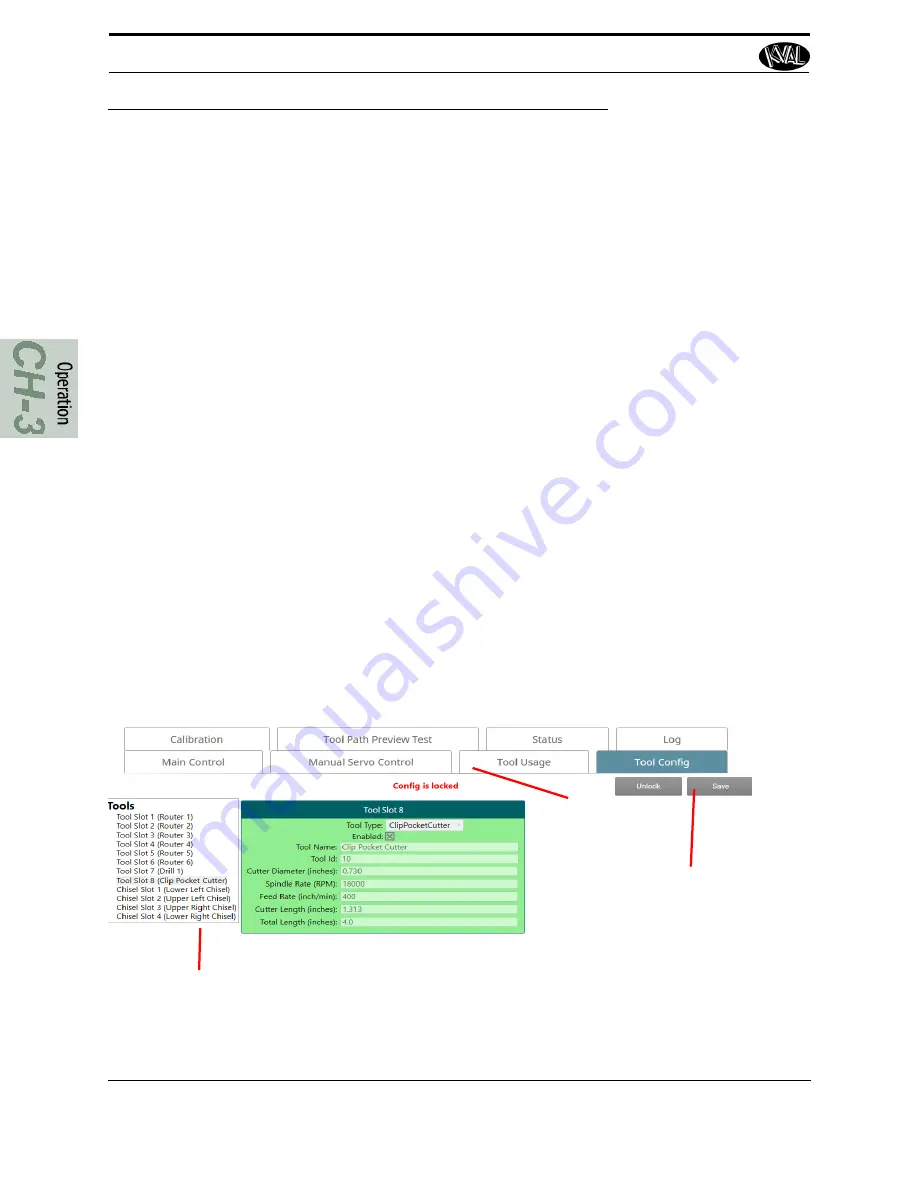

Select the

Tool Config Tab

.

Tool configuration can improve the speed and quality of cut by defining tool specifications, types

of materials being machine, parameters of the cut, and the frequency of the motor.

At this screen, specifications of the tool, type of material being cut, and process is entered and

saved to the database. This information is valuable to compute and provide the most precise cut

available.

Note:

The. Screen shot below is a from a sample machine. For tool identification for

the machines described in this manual,

see

General Operating Controls

The

Tool Config Screen

contains a sample of the following:

• List of the available tools.

• Pop-up menus to enter information about each tool (Specifications)

• The ability to adjust the method of chisel operation during machining.

• The ability to enable or disable specific tool slots

• The ability to name the tools to familiar names.

• The ability to lock and unlock the ability to enter data.

• Change the rate of machining (feed-rate, spindle speed, plunge feed, entry feed,

perimeter feed)

• Parameters of the cut (depth, passes through material, overlaps, skin priority)

• Chisels: Can change peck count (start of cut), corner location, and rate of machin-

ing.

Select Tab

List of Tools Available

Unlock, Lock, and

Save Data

Pop-Up Menu

Enter parameters to

tune the method of

machining

Summary of Contents for DL-NCD

Page 10: ...KVAL DL NCD Operation Manual Table of Contents ...

Page 28: ...How to Download the Service Application KVAL Operation Manual 1 18 ...

Page 30: ...Safety Sign Off Sheet KVAL Operation Manual 1 20 ...

Page 62: ...About the LiteCutout Feature Detail KVAL Operation Manual 2 32 ...

Page 94: ...Appendix About Backing up the Data KVAL Operation Manual 3 32 ...

Page 118: ...Appendix Servo Motor Drive Assembly Locations KVAL Operation Manual 4 24 ...

Page 139: ...About the Electrical Panels KVAL Operation Manual 5 21 I ...

Page 142: ......

Page 143: ......