4.

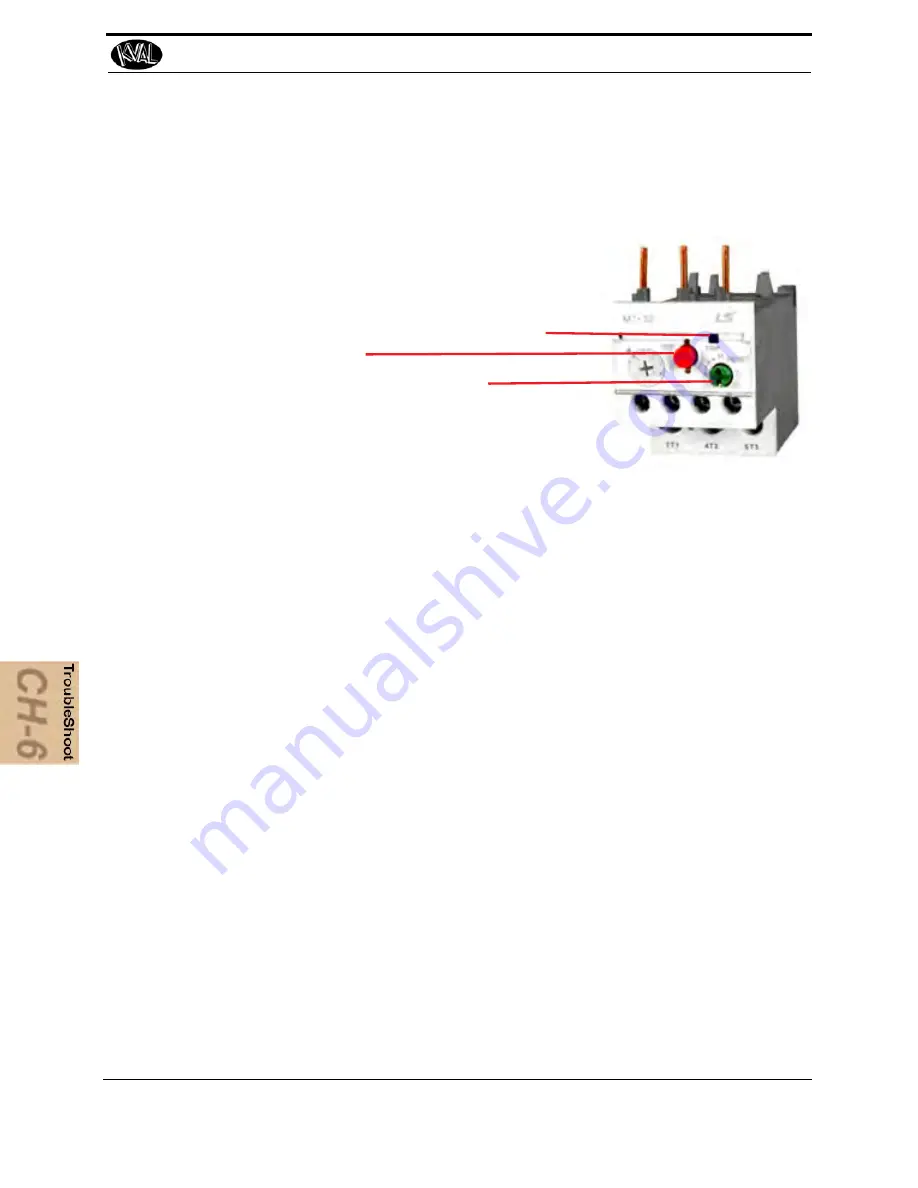

With the power off, check for motor overloads by pressing each reset button (usu-

ally at the bottom of the panel) in SEQUENCE. If one is tripped there will be a

slight resistance to touch and a “click” sound as it is reset.

Trip Indicator

Press Reset

Thermal Overload Relay

Test

Troubleshooting Electrical Problems

6-25

KVAL Operation/Service Manual

Check for Tripped Circuits

1.

Remove lock and tag outs on the main power sources.

2.

Manually close disconnect sensors and energize the control circuit or transformer

with its respective sensor. Check the Status Light Panel,. If all lights are observed,

there are no overloads or emergency stops tripped. See”

Troubleshooting with the

Status Light Panel

“below, for more information.

Note:

Most electrical problems are related to mechanical malfunction (e.g., stuck

motors, jammed chain, blocked photo sensors etc.)

Note:

If a solenoid valve is suspected, and not cleared in the air checks section (see),

it can be electrically jumped to check operation.

Troubleshooting with the Status Light Panel

The Status Light Panel is located on the Electrical Panel. All six lights are illuminated when the

system is in proper working order. The lights turn on in a sequence and will stop at the point

where a fault is first detected.

Summary of Contents for Edge-SS

Page 5: ...KVAL Edge SS Operation Service Manual ...

Page 12: ...KVAL Edge SS Line Operation Service Manual ...

Page 32: ...Safety Sign Off Sheet 1 20 KVAL Operation Service Manual ...

Page 35: ...Definitions 2 45 KVAL Operation Service Manual ...

Page 91: ...Definitions KVAL Operation Service Manual 2 56 ...

Page 109: ...System IT Administration 4 4 KVAL Operation Service Manual ...

Page 142: ...Collet Torque Values 5 33 KVAL Operation Service Manual ...

Page 143: ...Troubleshooting Electrical Problems 6 30 KVAL Operation Service Manual ...

Page 173: ......

Page 177: ......

Page 178: ......

Page 179: ......