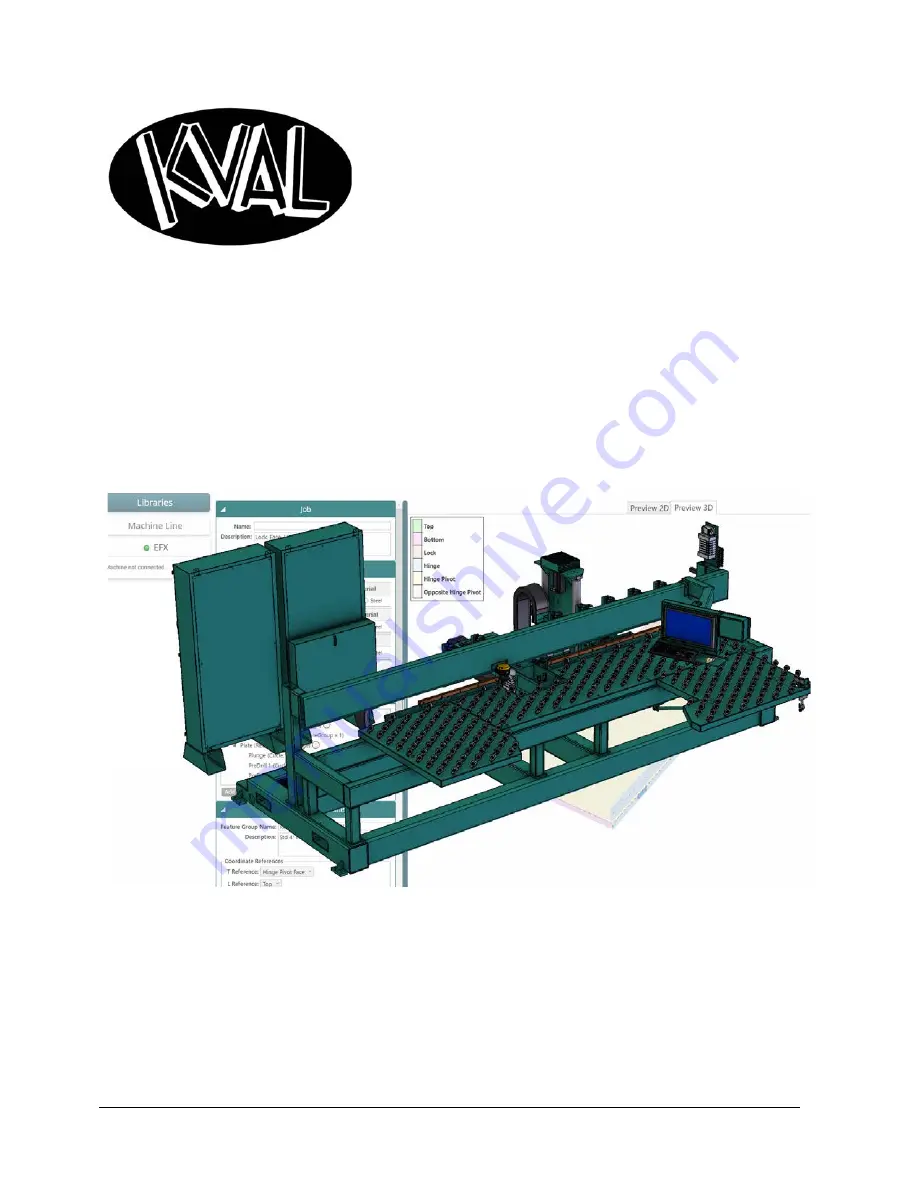

Summary of Contents for EFX

Page 10: ...KVAL EFX Manual Table of Contents ...

Page 32: ...Safety Sign Off Sheet KVAL Operation Manual 1 22 ...

Page 66: ...About the LiteCutout Feature Detail DL NCD Only KVAL Operation Manual 2 34 ...

Page 95: ...Appendix About Backing up the Data 3 29 KVAL Operation Manual ...

Page 112: ...Step 4 Calibrate the Face Axes KVAL Operation Manual 4 17 X Y Z X Y Z Y ...

Page 121: ...Routers How to Isolate and Calibrate a Specific Router KVAL Operation Manual 4 26 ...

Page 136: ......

Page 138: ...Index 1 2 Kval EFX ...

Page 139: ......