Step 6: Calibrate the Edge Carriage

KVAL Operation Manual

4-20

Step 6: Calibrate the Edge Carriage

Process to Calibrate the Edge Carriage

In this calibration process, cut a known door lock on the edge of the door. Measure the location of

the cut.

1.

Before calibrating the tools, update the Tool Configuration of the tool being calibrated.

See “About Using Tool Configuration” on page 3-23.

2.

Create a

Lock Job

of your choice with a corner radius of 0.25 inches and a depth of

0.25 inches.

3.

Add

Door Job

to the

Queue

.

4.

Once the cut has been made, check the location of the cut.

5.

Perform the Left Hand Rule at the lock side of the door to determine axis direction. See

illustration below.

• If the location is out of specification in the

length

of the door edge, the

X-Axis

needs to be adjusted.

• If the location is out of specification in the

width

of the door edge4, the

Y-Axis

needs to be adjusted.

• If the plunge cut is out of specification, check the

Configuration Menu

then verify

the

Z-Axis.

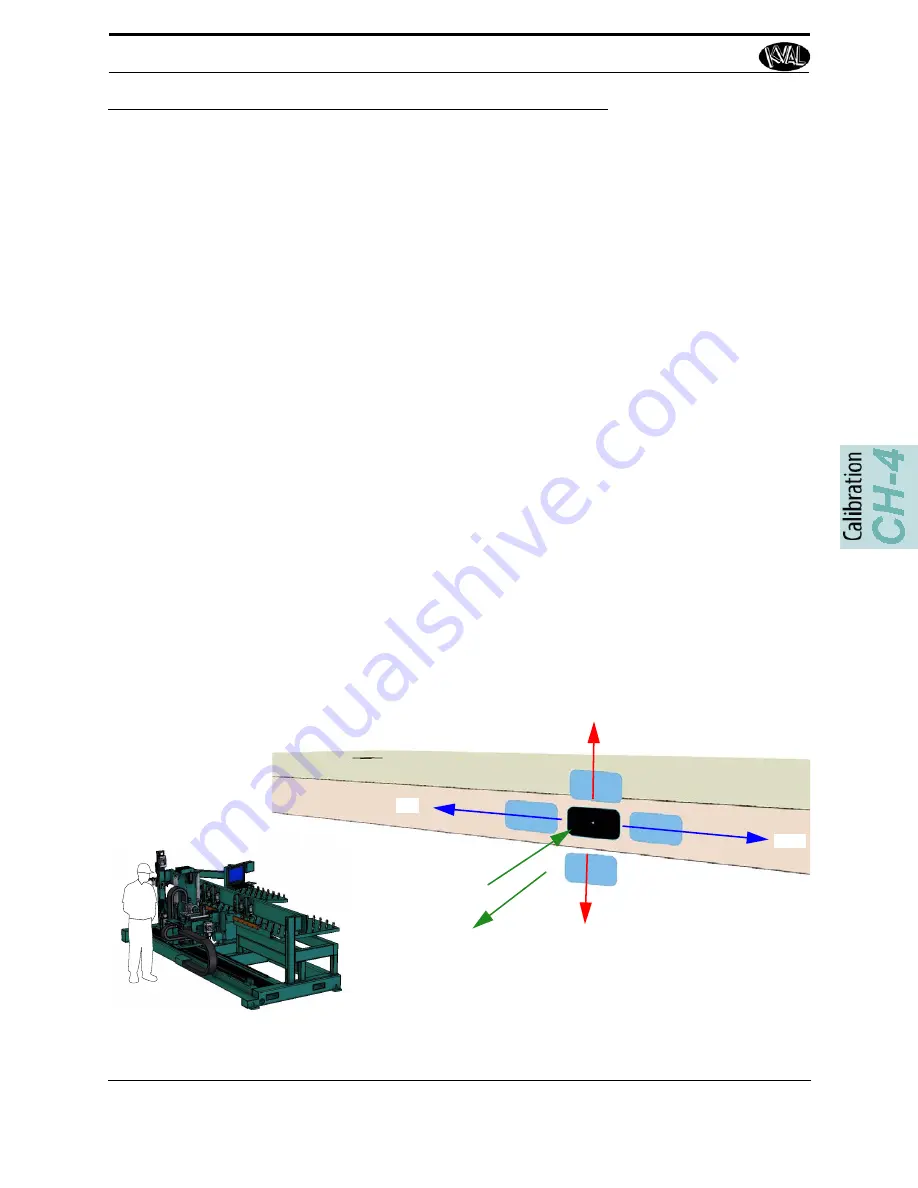

Edge Axis Calibration Reference Cut

The figure below, shows a sample reference cut and the type of offset to input into the calibration

menu.

See “How to Enter Calibration Data” on page 4-7

+

X

+

Y

+

Z

-

X

-

Z

-

Y

Summary of Contents for EFX

Page 10: ...KVAL EFX Manual Table of Contents ...

Page 32: ...Safety Sign Off Sheet KVAL Operation Manual 1 22 ...

Page 66: ...About the LiteCutout Feature Detail DL NCD Only KVAL Operation Manual 2 34 ...

Page 95: ...Appendix About Backing up the Data 3 29 KVAL Operation Manual ...

Page 112: ...Step 4 Calibrate the Face Axes KVAL Operation Manual 4 17 X Y Z X Y Z Y ...

Page 121: ...Routers How to Isolate and Calibrate a Specific Router KVAL Operation Manual 4 26 ...

Page 136: ......

Page 138: ...Index 1 2 Kval EFX ...

Page 139: ......