Stand: 19.03.12

Seite 16

KW Hydraulik GmbH

Tel.:

03675/42198-0

Köppelsdorfer Str. 132

Fax:

03675/42198-11

D-96515 Sonneberg

e-mail:

info@kw-hydraulik.de

Germany

Internet: www.kw-hydraulik.de

SSBZ

SSBZ

SSBZ

SSBZ

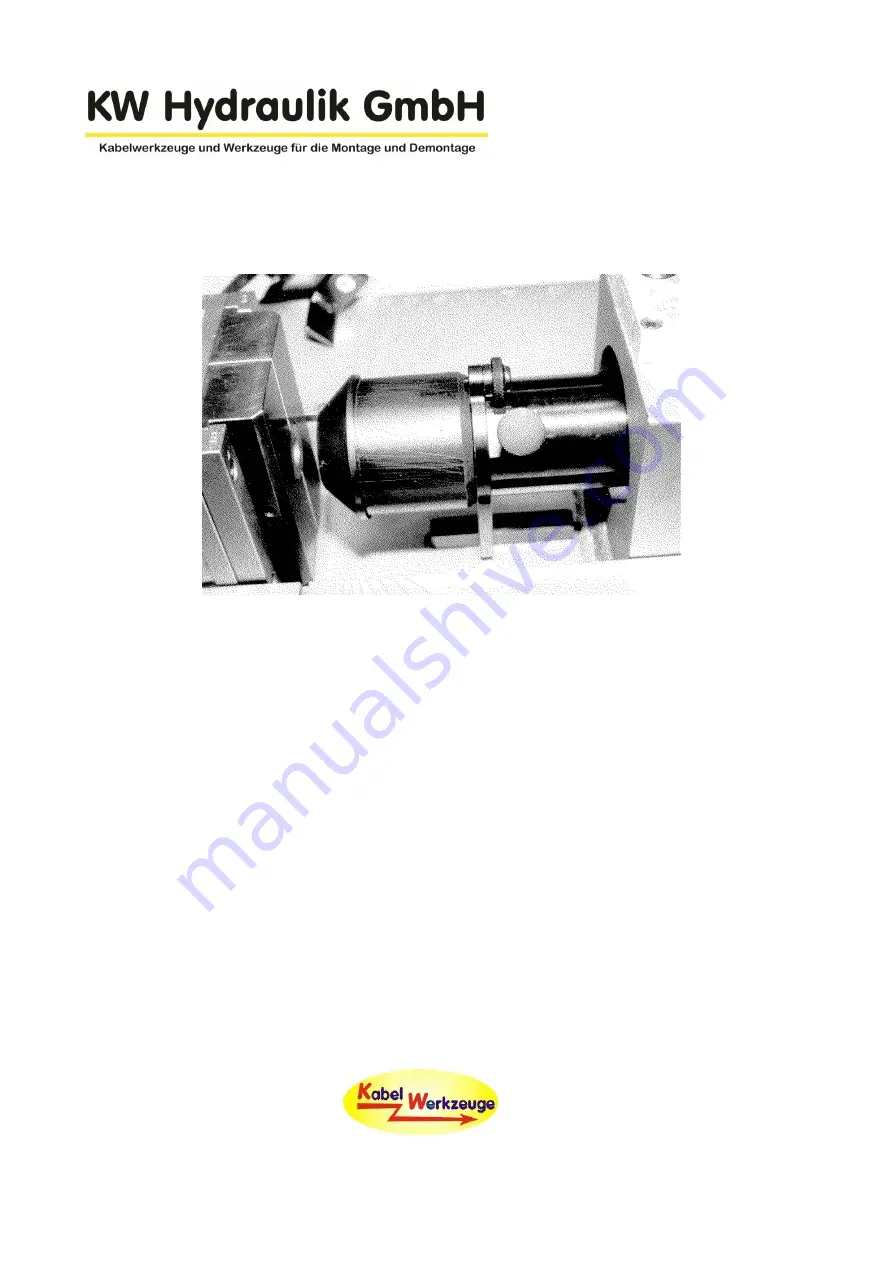

Now the appliance is ready (picture 14).

picture 14: punching tool 1 in the SSBZ

The dismantling of the tools are in a reversed turn. For the removing of the hole-punch

reception you have to move the die-reception by the touch-control a little bit forward, to

untie the latching-bolt.

You should use cutting-spray for the increase of the lifetime of the punching-insertion.

punching tool 2

You can make all sorts of working with the punching tool 2 (picture 15) like the punching

tool 1. In addition it is good for punching lamina-rails.

The punching tool 2 is a little bit different to the punching tool 1. At the front side of the

latch it has a latch-plate which locks the punch very exactly. The latch is hold from

permanent magnets. By changing the punch you have to remove the latch and the latch-

plate. There is not a female-screw which you have to untie before.

The shaft of the punches for the punching tool 2 has two centring. After a insertion of a

punch you have to fix it with both worm-bolts of the hole-punch reception on this centring.

Afterwards put the latch on the latch-plate.

The change of a die and the insertion of die-holders as well as a hole-punch reception in

the SSBZ is the same as at the punching tool 1.