Rys.10

2

1

EN

PL

OPERATING INSTRUCTIONS

FOAMER OPERATION

Screw the pump off the head - to do this, lock the piston rod (fig. 8b/pos. 1) in the cylinder brackets (fig. 8b/pos. 2).

Unscrew the pump counterclockwise, holding the piston rod (fig. 8b/pos. 1).

Insert the strainer (fig. 9/pos. 2) to the head cup (fig. 9/pos. 1) and pour in the previously prepared spray liquid

in accordance with manufacturer guidelines.

In order to secure the spraying nozzle against contamination when filling the tank with the spray liquid,

it is recommended to rest the lance on the head (nozzle facing upwards).

Remove the strainer (fig. 9/pos. 1) from the head cup (fig. 9/pos. 2). Screw the pump (fig. 1/pos. 5) into

the head (fig. 1/pos. 4). To do this, lock the piston rod (fig. 8/pos. 2) in the cylinder brackets (fig. 11/pos.

2). Remember that the connection must be airtight. The locked piston rod may be used as a transport handle.

Clean any dirt off the strainer.

Move the foamer to the work site. Use the piston rod (fig. 7c) to pump the sprayer (around 20 full motions) until

the safety valve operates (fig. 7a/pos. 1). As soon as the safety valve opens (fig. 7a/pos. 1), maximum tank

pressure has been reached. Monitor the tank pressure on the pressure gauge (fig. 12/pos. 3).

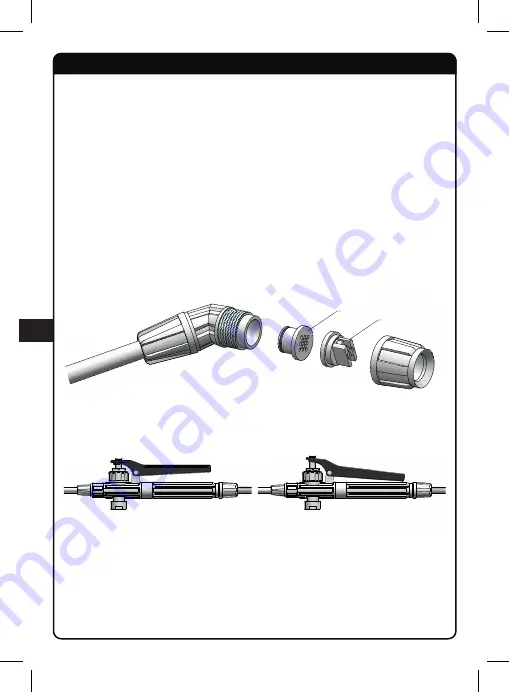

Point the lance tip (fig. 10) at the location to be sprayed.

Press the handle valve lever (fig. 11b). Spraying should be performed according to main wind direction.

Fig.11a

Fig.11b

16

RU

DE