WARRANTY AND SERVICE

WARRANTY CARD - WARRANTY CONDITIONS

KWAZAR CORPORATION Sp. z o.o provides full warranty and post-warranty service.

1. An applicator that is sent for repair (regardless of cause) must be complete and clean - free of any spray

liquid residue.

2. Warranty repairs will be performed only if a completed warranty card and proof of purchase is provided

with the applicator.

3. Warranty and post-warranty repairs are conducted at the seat of the company and in Authorised KWAZAR

Service Centres - the list is available at www.kwazar.com.pl in the SERVICE tab.

SPARE PARTS AND ACCESSORIES

Spare parts are available for the applicator. For more information, visit www.kwazar.com.pl or the web store

at www.sklep.kwazar.com.pl

TROUBLESHOOTING

Always depressurise the tank before performing any maintenance or repair work!!!

KWAZAR CORPORATION Sp. z o.o. reserves the right to change product composition and design.

EN

PL

19

RU

DE

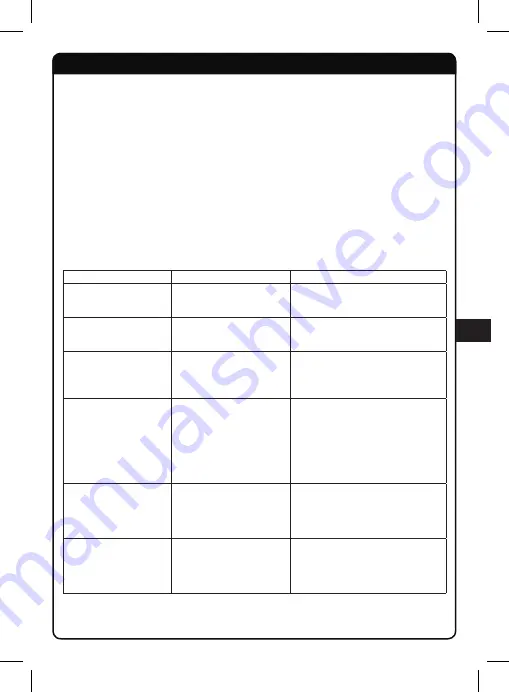

SYMPTOMS

CAUSE

REMEDY

Low lance output pressure

(fig. 1/pos. 1).

Clogged nozzle on the lance tip

(fig. 7/pos. 1).

Unscrew the lance tip and remove spraying nozzle

(fig. 7/pos. 1).

Irregular stream from the spraying

nozzle (fig. 7/pos. 1).

Clogged nozzle on the lance tip

(fig. 7/pos. 1).

Unscrew the lance tip and remove spraying nozzle

(fig. 7/pos. 1).

Pressure drop in the tank (fig. 1/

pos. 8), spray liquid appears in the

pump cylinder (fig. 1/pos. 5).

Damaged head seal on the end

of the cylinder pump (fig. 9/pos. 3).

Depressurise the tank with the safety valve (fig. 1/pos.

6). Remove the pump (fig. 1/pos. 5) and the mixer.

Check the condition of the head seal. Replace if dama-

ged. Reassemble in the reverse order.

No pressure in the tank

(fig. 1/pos. 8) when pumping.

Damaged seal (fig. 9/pos. 2)

on the pump piston rod (fig. 1/pos. 5)

Depressurise the tank with the safety valve (fig. 1/

pos. 6). Remove pump (fig. 1/pos. 5). Slide the pi-

ston rod out of the cylinder as far as possible. Holding

the cylinder, turn the piston handle counterclockwise,

which will undo the guides and allow you to remove

the piston from the cylinder. Check the condition of the

piston seal (fig. 9/pos. 2). Replace if damaged. Apply

a small amount of silicone oil (included). Reassemble

by following the procedure backwards.

Safety valve (fig. 1/pos. 6) does

not close or open. Pressure in tank is

decreasing (fig. 1/pos. 8)

Damaged safety valve.

Lubricate safety valve (fig. 1/pos. 6). With the safety

valve open, apply a few drops of silicone oil inside and

operate it back and forth a little. If the problem persists,

replace the valve.

No spray liquid stream.

Suction tube fell off the hose.

Depressurise the sprayer with the safety valve (fig. 1/

pos. 6). Remove the hose and properly insert the suc-

tion tube as far as possible applying a turning motion,

then reconnect the hose to the sprayer head.