23

KWE P

/N 3940

46 Ve

rsatronik

502 a

nd 502D

MODBUS G

atewa

y V1

.0 F

eb

2

014 Te

chni

ca

l i

nformation subj

ec

t to

ch

ange

w

ithout noti

ce

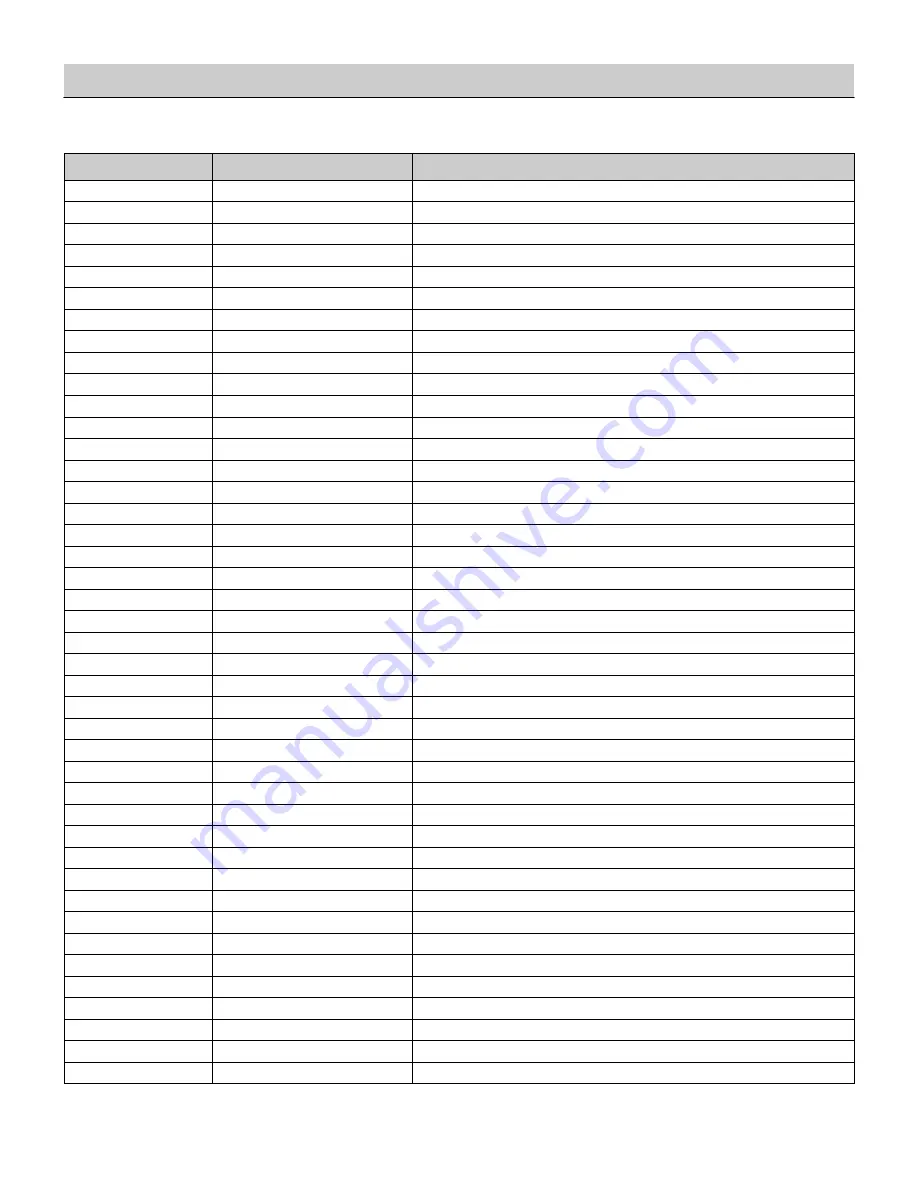

Appendix A—Fault Codes Continued

Error codes for Viessmann control units based on controls/equipment installed

Fault Codes Continued

C5

Fault, speed controlled pump heating circuit 1 (KM-BUS)

C6

Fault, speed controlled pump heating circuit 2 (KM-BUS)

C7

Fault, speed controlled pump heating circuit 3 (KM-BUS)

C8

Fault, water level control

C9

Fault, maximum pressure

CA

Fault, minimum pressure/maximum pressure 2

Cb

Fault, maximum pressure 2

CC

Reserved, external periphery

Cd

Communication fault, Vitocom 300 (KM-BUS)

CE

Communication fault, fault indicator module (KM-BUS)

CF

Communication fault: wrong LON module

d1

Burner fault, boiler

d4

Fixed high limit fault, boiler

d5

Cascade: boiler is not responding

d6

External fault 1, plug-in adaptor

d7

External fault 2, plug-in adaptor

d8

External fault 3, plug-in adaptor

dA

Short circuit, room temperature sensor heating circuit 1

db

Short circuit, room temperature sensor heating circuit 2

dC

Short circuit, room temperature sensor heating circuit 3

dd

Interruption, room temperature sensor heating circuit 1

dE

Interruption, room temperature sensor heating circuit 2

dF

Interruption, room temperature sensor heating circuit 3

E0

Fault, external participant/device connected to LON

Fault Code (hex)

Description

E4

Fault power supply voltage

E5

Internal fault combustion control unit

E6

Flue gas/air supply system blocked

F0

Communication fault combustion control unit

F1

Flue gas temperature limit has tripped

F2

Temperature limit has tripped

F3

Flame signal is present at burner start

F4

Flame signal is not present

F5

Air pressure switch not open for burner start

F6

Gas pressure switch not open for burner start

F7

Air pressure sensor short circuit or offset value outside of tolerances

F8

Fuel valve closure delayed

F9

Blower speed too low at burner start

FA

Blower speed too high at burner start

FC

Control of modulation valve defective

FD

Fault combustion control unit

FE

Coding plug defective or wrong EMV error

FF

Internal fault

Fault Code (Dec)

197

198

199

200

201

202

203

204

205

206

207

209

212

213

214

215

216

218

219

220

221

222

223

224

228

229

230

240

241

242

243

244

245

246

247

248

249

250

252

253

254

255