Manual handling in the corridor

4. Use guide

4.7 Array layout proposal

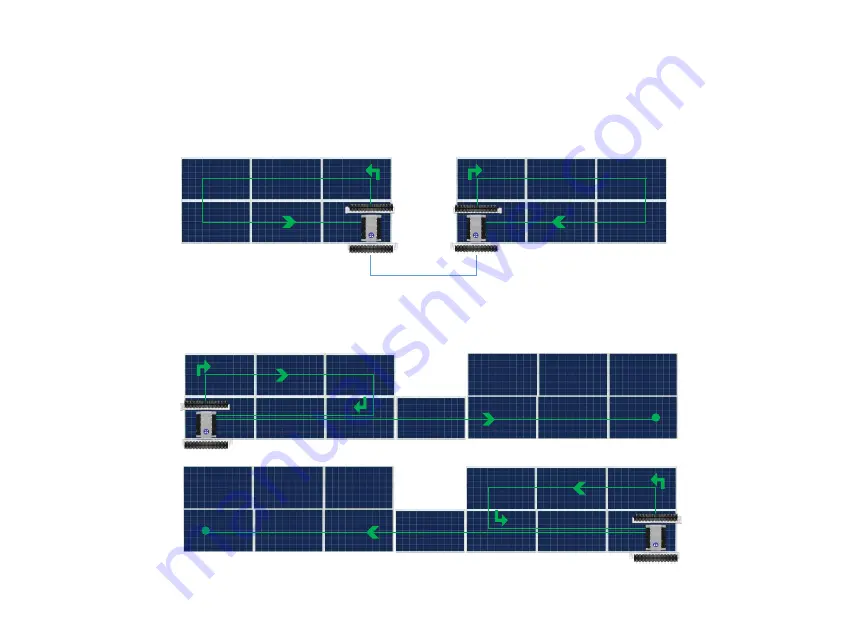

4.7.3 Comparison of connection effects between adjacent arrays

Photovoltaic array operation path at adjacent intervals

Cleanup missions under berthing at adjacent angles

Operation path of horizontal connection at the bottom of adjacent

horizontal photovoltaic arrays

First assignment

Second assignment

The bottom of the array

The bottom of the array

The bottom of the array

22