12

. COOLING SYSTEM

12-20

Downtown 125 i

INSPECTION

Suspend the thermostat in a pan of water

over a burner and gradually raise the water

temperature to check its operation.

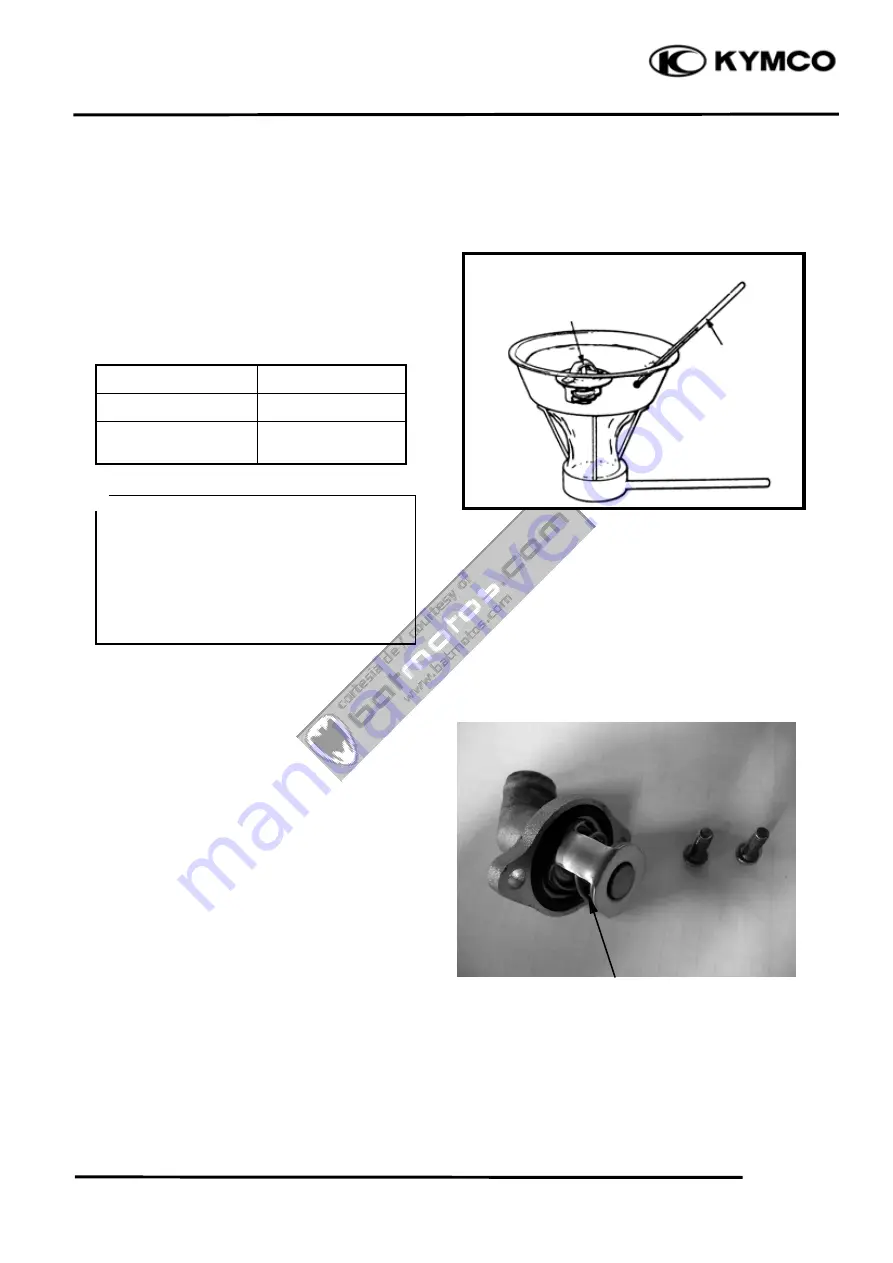

Technical Data

Begins to open

71

±

1.5°C

Full-open

80°C

Valve lift

3.5 mm (0.14 in)

minimum

ASSEMBLY

Thermostat assembly is in the reverse order

of disassembly.

Thermostat Housing

Thermostat

Thermometer

•

Do not let the thermostat touch the pan

as it will give a false reading.

•

Replace the thermostat if the valve

stays open at room temperature.

•

Test the thermostat after it is opened for

about 5 minutes and holds the

temperature at 70

℃

.

*

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com