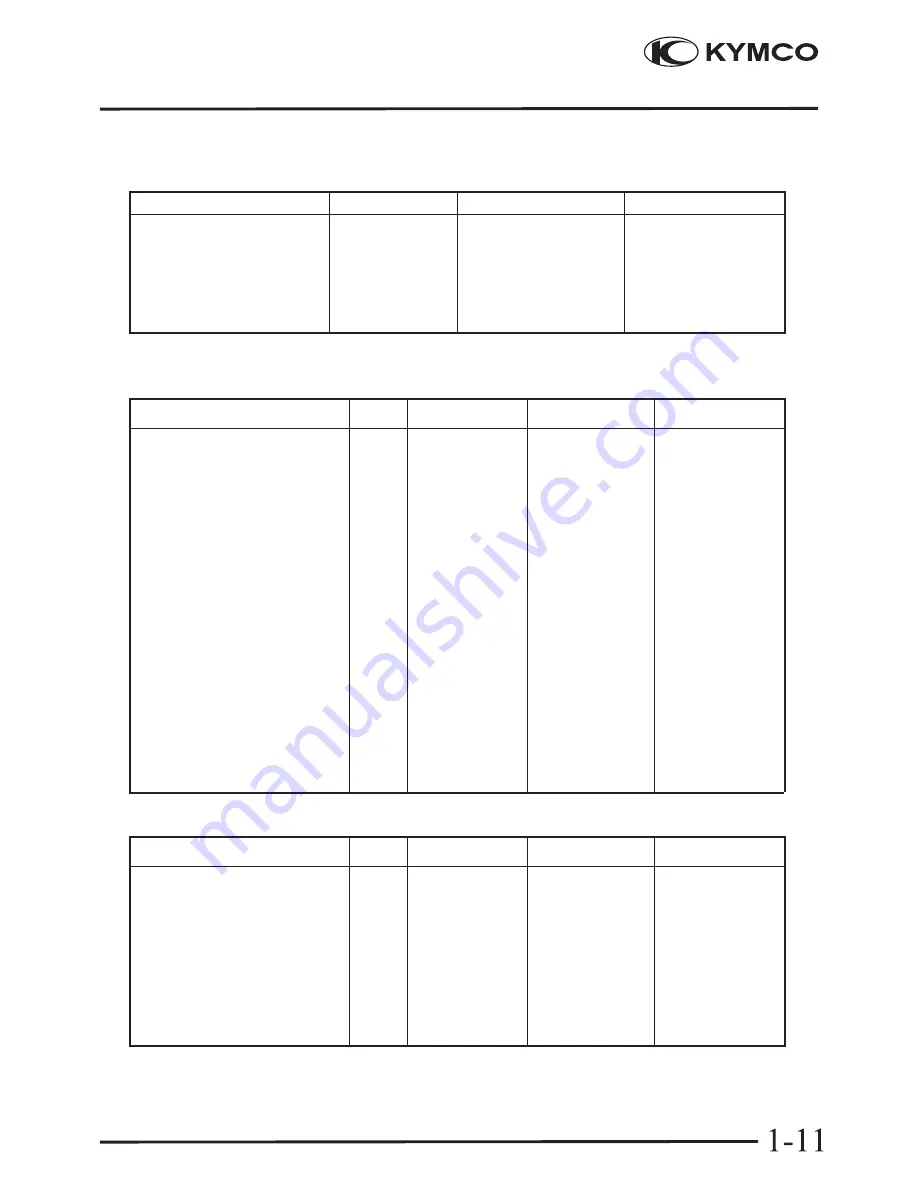

TORQUE VALUES

STANDAR TORQUE VALUES

Item

Torque (kg -

f m)

Item

Tor

(kg -

que

f m)

5mm bolt, nut

6mm bolt, nut

8mm bolt, nut

10mm bolt, nut

12mm bolt, nut

0.45~0.6

0.8~1.2

1.8~2.5

3.0~4.0

5.0~6.0

5mm screw

6mm screw, SH bolt

6mm flange bolt, nut

8mm flange bolt, nut

10mm flange bolt, nut

0.45~0.6

0.7~1.1

1.0~1.4

2.4~3.0

3.0~4.5

Torque specifications listed below are for important fasteners.

ENGINE

Item

Qty

Thread dia.(mm)

Torque (kgf-m)

Remarks

Cylinder head bolt A

Cylinder head bolt B

Oil filter screen cap

O2 sensor

Cylinder head cover

Tappet adjusting hole cap

Cam chain set plate

Engine oil drain bolt

Clutch outer nut

Clutch drive plate nut

Starter motor mounting bolt

Oil pump bolt

Drive face nut

Spark plug

A.C. Generator flywheel

Cam chain tensioner pivot

6

6

30

12

6

30

6

12

12

28

6

6

12

10

12

6

FRAME

Item

Qty

Thread dia.(mm)

Torque (kgf-m)

Remarks

Steering stem lock nut

Front axle

Rear axle nut

Rear shock absorber upper bolt

Rear shock absorber lower bolt

Muffler exh. Pipe

Bc1

14

16

10

10

8

6.0~6.5

1.5~2.5

11~13

3.5~4.5

3.5~4.5

1.8~2.0

U - nut

U - nut

1. GENERAL INFORMATION

- 11 -

0.7~1.1

0.7~1.1

2.0~3.0

0.7~1.1

0.8~0.9

1.0~2.0

1.0~1.4

2.0~3.0

5.0~6.0

5.0~6.0

0.8~1.2

0.7~1.1

5.5~6.5

1.0~1.4

5.0~6.0

0.8~1.2

DOWNTOWN 125i