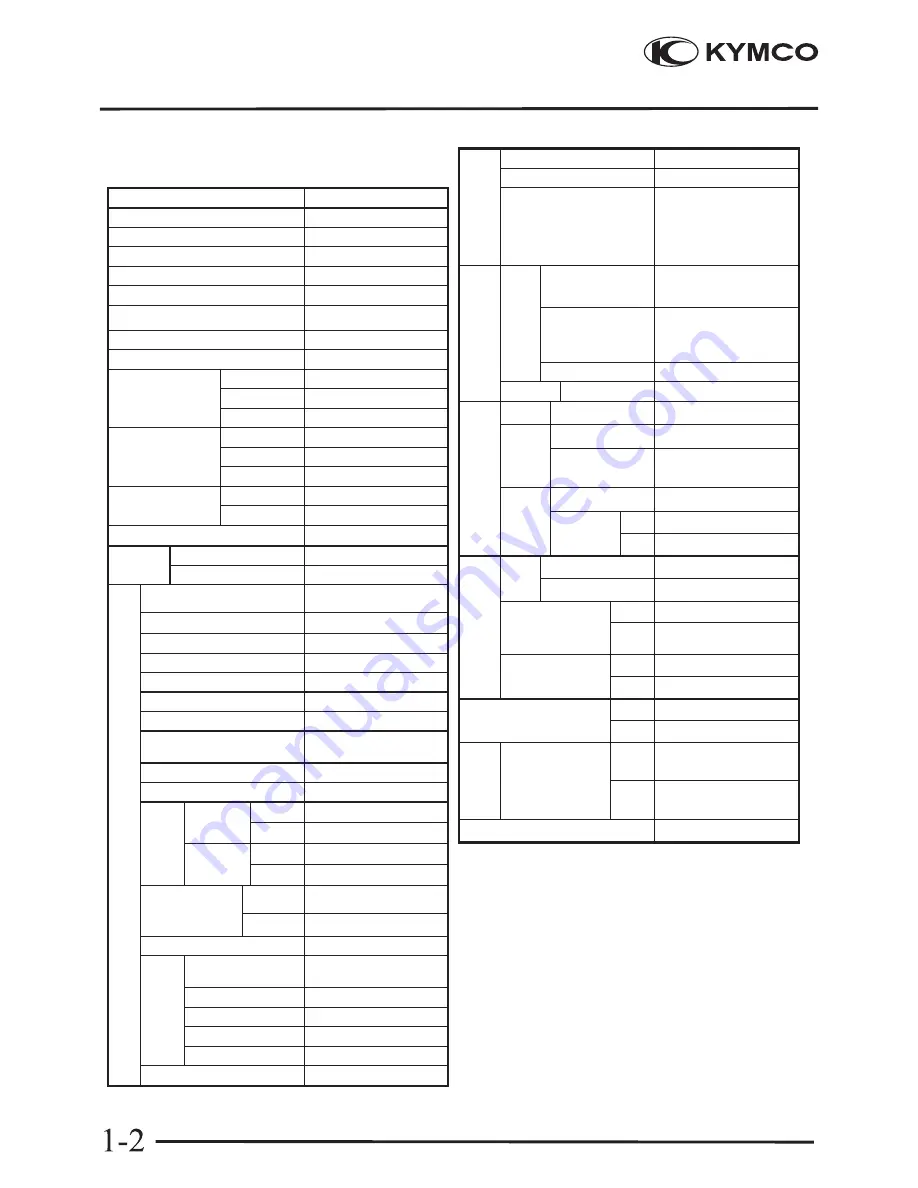

1. GENERAL INFORMATION

SPECIFICATIONS

- 2 -

Name

DOWNTOWN125i

Model No.

SK25AA

Overall length

2200mm

Overall width

800 mm

Overall height

1410 mm

Wheel base

1542 mm

Engine type

O.H.C.

Displacement

124.8cc

Fuel Used

92# nonleaded gasoline

Front wheel

68

Net weight (kg)

Rear wheel

96

Total

164

Front wheel

70

Gross weight

(kg)

Rear wheel

104

Total

178

Front wheel

120/80-14

Rear wheel

150/70-13

RR Ground clearance

140 mm

Perform- Braking distance (m)

7.9m/30km/h

ance

Min. turning radius

2600mm

Starting system

Starting motor

Type

liquid cooled 4 stroke

Cylinder arrangement

Single cylinder

Combustion chamber type

Semi-sphere

Valve arrangement

O.H.C.4V

Bore x stroke (mm)

54 x 54.5

Compression ratio

11.7:1

Compression pressure

(kg/cm

²

)

15

Max .horsepower (ps/rpm)

15/8750~9000

Max. torque (kg m/rpm)

1.17/8500~8750

Intake

Open

8 °BTDC

Port

(1mm)

Close

31° BTDC

timing Exhaust

Open

32° BTDC

(1mm)

Close

6 °BTDC

Valve

Intake

0.10 mm

clearance

Exhaust

0.10 mm

Idle speed (rpm)

1850rpm

Lubrication type

Forced pressure &

Wet sump

Oil pump type

Inner/outer rotor type

Oil filter type

Full-flow filtration

Oil capacity

1.2 L

Exchanging capacity

1.0 L

Cooling Type

Liquid cooling

Tires

Engine

Lubrication

System

Air cleaner type & No

Paper element, wet

Fuel capacity

12.5 L

Throttle type

Butterfly type

Type

ECU

Spark plug

NGK CR7E

Spark plug gap

0.6

~

0.7mm

Battery

Capacity

12V10AH

Clutch Type

Dry multi-disc clutch

Type

Non-stage transmission

Operation

Automatic centrifugal

type

Type

Two-stage reduction

Reduction 1st

0.83~2.2

ratio

2nd

10.41

Front

Caster angle

28°

Axle

Trail length

140mm

Tire pressure

Front

2.0

(kg/cm

²

) 1

person

Rear

2.25

Turning

Left

40

?

angle

Right

40

?

Brake system

Front

Disk brake

type

Rear

Disk brake

Front

Telescope

Suspension

type

Rear

DOUBLE SWING

Frame type

PIPE UNDER BONE

Red

u

ctio

n

Gear

Transmis-

sion

Gear

Fuel

System

Power

D

rive

System

Electrical

Equip.

Ignition

System

Moving

Device

Damping

Device

DOWNTOWN 125i