18

.

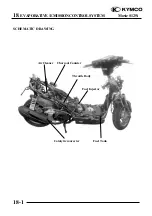

EVAPORATIVE / EMISSION CONTROL SYSTEM Movie S 125i

18-4

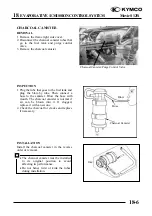

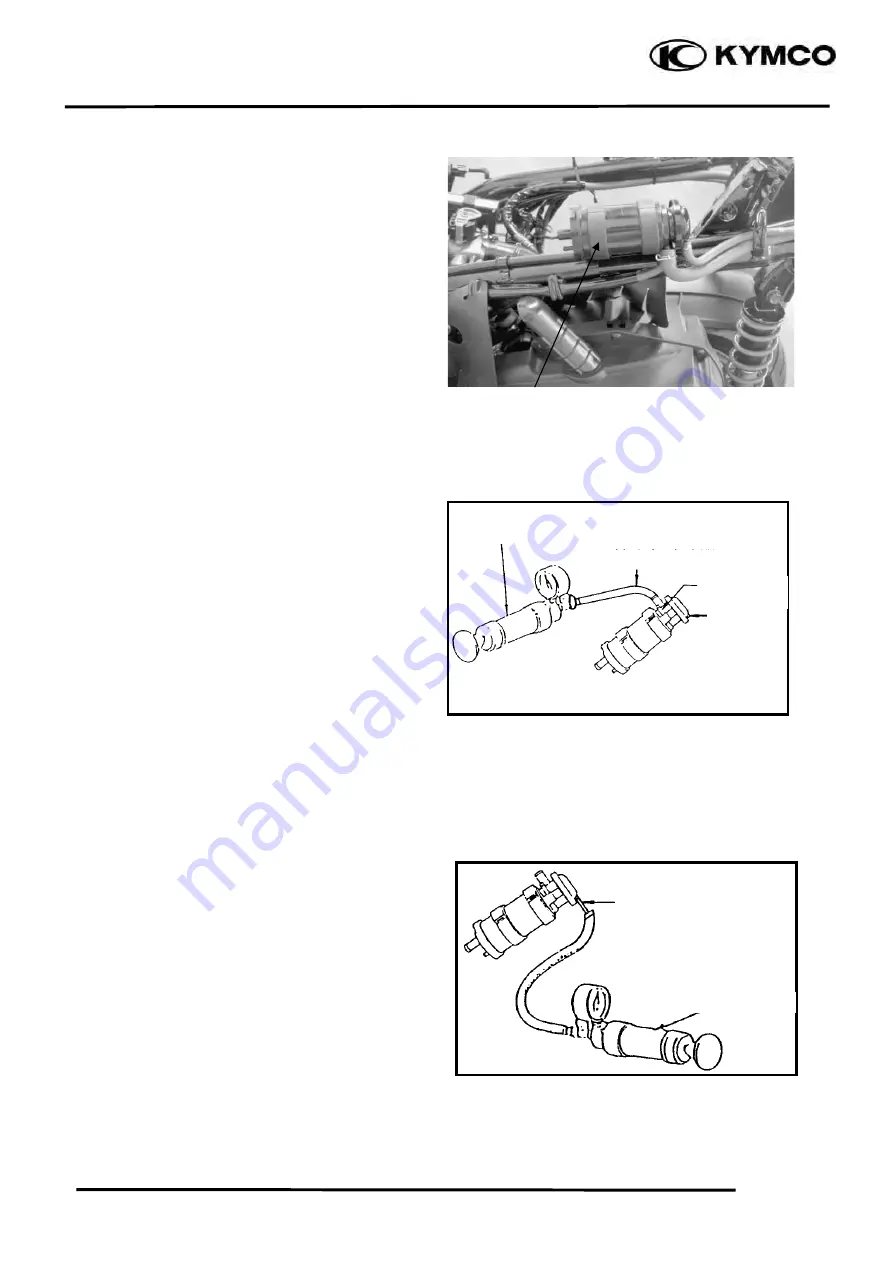

PURGE CONTROL VALVE

REMOVAL

1. Remove the body cover.

2. Disconnect the purge control valve

vacuum tube that goes to the throttle body

and the tubes that go to the air cleaner and

charcoal canister. Remove the charcoal

canister/purge control valve.

INSPECTION

Connect a vacuum pump to the purge

control valve tube that goes to the air cleaner

and apply vacuum pressure of 250mm/Hg.

The specified vacuum must be maintained

for one minute. Replace the purge control

valve with a new one if vacuum is not

maintained.

Connect a vacuum pump to the purge

control valve tube that goes to the carburetor

vacuum tube and apply vacuum pressure of

45mm/Hg. The specified vacuum must be

maintained for one minute. Replace the

purge control valve with a new one if

vacuum is not maintained.

To Air Cleaner

Vacuum Pump

To

Throttle

Body

To Fuel Tank

To Throttle Body

Vacuum Pump

Purge Control Valve

Summary of Contents for KYMCO Movie S 125i

Page 17: ...1 GENERAL INFORMATION Movie S 125i 1 14...

Page 23: ...1 GENERAL INFORMATION Movie S 125i 1 20 WIRING DIAGRAM...

Page 54: ...5 Fi INJECTION SYSTEM MOVIES125i 5 2 Fi PARTS DRAWING...

Page 85: ...6 0 6 6 ENGINE REMOVAL INSTALLATION Movie S 125i...

Page 90: ...7 0 7 7 CYLINDER HEAD VALVES Movie S 125i...

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ...10 10 FINAL REDUCTION 10 0 Movie S 125i...

Page 116: ...11 11 CRANKCASE CRANKSHAFT 11 0 Movie S 125i...

Page 123: ...12 FRONT WHEEL BRAKE SUSPENSION 12 1 Movie S 125i...

Page 129: ...12 FRONT WHEEL BRAKE SUSPENSION 12 7 Movie S 125i...

Page 139: ...13 13 0 13 REAR WHEEL REAR BRAKE REAR SUSPENSION Movie S 125i...

Page 157: ...15 IGNITION SYSTEM 15 2 Movie S 125i IGNITION CIRCUIT...

Page 160: ......

Page 161: ......

Page 169: ......

Page 170: ......

Page 171: ......

Page 172: ......

Page 173: ......

Page 174: ......

Page 175: ......

Page 176: ......