3-19

3

CC127D

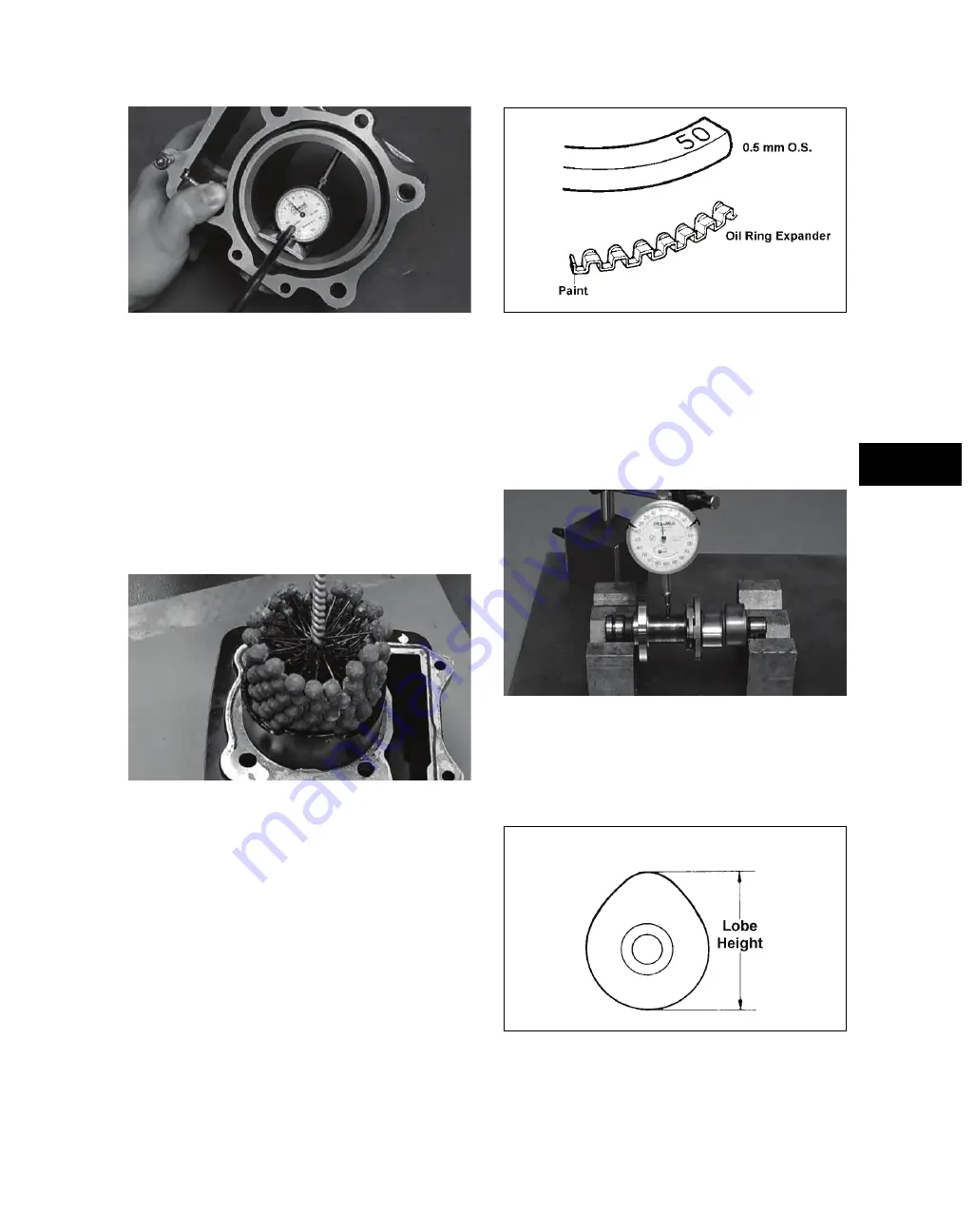

2. Wash the cylinder in parts-cleaning solvent.

3. Inspect the cylinder for pitting, scoring, scuffing,

and corrosion. If marks are found, repair the sur-

face using a ball hone.

NOTE: To produce the proper 60° cross-hatch

pattern, use a low RPM drill (600 RPM) at the rate

of 30 strokes per minute. If honing oil is not avail-

able, use a lightweight petroleum-based oil. Thor-

oughly clean cylinder after honing using soap and

hot water. Dry with compressed air; then immedi-

ately apply oil to the cylinder bore. If the bore is

severely damaged or gouged, replace the cylinder.

CC390D

4. If any measurement exceeds the limit, bore the

cylinder and install an oversized piston or replace

the cylinder.

NOTE: Oversized piston and rings are available.

The oversized piston and rings are marked for

identification.

ATV-1068A

Measuring Camshaft Runout

NOTE: If the camshaft is out of tolerance, it must

be replaced.

1. Place the camshaft on a set of V blocks; then posi-

tion the dial indicator contact point against the

shaft and zero the indicator.

CC283D

2. Rotate the camshaft and note runout; maximum

tolerance must not exceed specifications.

Measuring Camshaft Lobe Height

1. Using a calipers, measure each cam lobe height.

ATV1013A

2. The lobe heights must not exceed minimum speci-

fications.

Summary of Contents for MXU 450i

Page 17: ...Oil level stick...

Page 23: ...Low range High range Neutral Reverse...

Page 25: ...1 mm 0 039 in...

Page 126: ...A B...

Page 127: ...LCD Gauge Connector LCD Gauge Connector...

Page 134: ...9 4 NOTES...

Page 135: ......